IIoT can bring significant benefits to industries and companies that understood their importance have already implanted the technology and are reaping the rewards.

Connected Warehouse

Connected warehousing is a testament to how IIoT is useful in varied areas of industries like inventory management. Leading eCommerce companies are now utilizing connected robots to meet their shipping requirements. The IIoT-controlled warehouse ensures that each package goes in and out of the facility seamlessly. With sensors, machines can work with minimal human supervision. Since robots don’t get tired, they can work day and night without any problem.

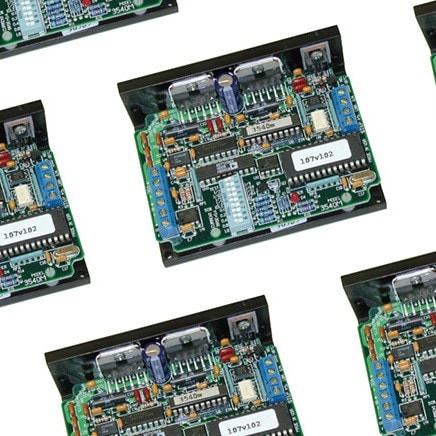

Automated Production

The reason why we are not entirely automating production is that it is tough to detect errors if machines worked all on their own. However, that is changing now with a combination of intelligent machines and data. Companies can create smart tools that will help to create a more efficient production floor guided by real-time data. The benefit of such a system is that the margin for errors to happen reduces significantly.

Self-Aware Vehicles

Many logistics companies have started fitting their vehicles with an array of sensors to study vehicle behavior under different conditions. Such a vehicle can alert about impending repairs or maintenance to ensure that it is working correctly. The sensors are also useful to monitor parts that undergo high dynamic forces to see if they show any signs of failure.

Besides, logistics companies can get real-time insights into driver behavior and traffic conditions. This data helps the owner to take necessary actions in case if the driver is overspeeding. The insights also help in optimizing the route for the driver to avoid congested areas, save on fuel, and ensure faster last-mile delivery.

Self-Aware Production Lines

Imagine using that same technology in production lines where machines are always working. These are instances where a machine going out of commission can cause severe delays in production. With IIoT, sensors analyze the health of the machines in real-time. If the sensor notices errors in the machine’s performance, it alerts the company to consider preventive maintenance before the entire assembly line goes out of service.

Conclusion

Industries that have implemented IIoT have seen that maintenance costs have dropped 30%, and machine specific failures saw a dramatic decline of 70%. So there is no question about the success of IIoT in industries.

The only question is, when are you going to implement it in your company?