Dual OMEGACLAD TM Thermocouple Cable

Dual OMEGACLAD TM Thermocouple Cable

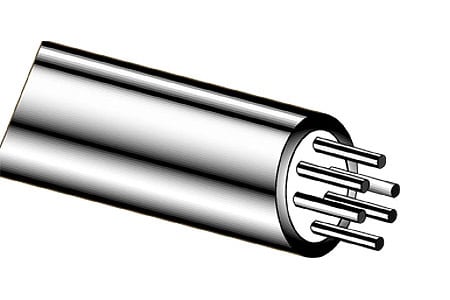

A Mineral insulated cable (MI cable) is a specialized type of cable used in high temperatures or harsh environmental conditions because it has low flammability, even when operating at high temperatures. It resists oxidation and enables precise measurement.

The metal sheath that clads MI cable helps to protect the thermocouple wires from oxidation when used in chemically active or wet environments. Corrosion resistance makes mineral insulated cable ideal for use in areas where failure and replacement could be dangerous or even impossible. For example, MI cable is used in nuclear plants to monitor core temperatures. It would be extremely dangerous if the temperature controllers were not receiving accurate readings, and it would be difficult to repair or replace cables in that environment.

The mineral fillings in MI cables provide excellent non-reactive insulation, preventing the thermocouple wires from contact with each other or with caustic substances such as oils, solvents or water. This helps to ensure that the thermocouple probes remain accurate, critical in applications such as heat treating or sintering where the quality of the product could be adversely affected by temperature fluctuations.

The insulation in ineral insulated cables does not burn, which makes it ideal for applications where fire could be catastrophic. Medical devices, power plants, and oil rigs are examples of places where installation of MI cables makes operations safer.

Molten Metal

Since the thermocouple probes are protected from contact with other electrically active wires by the insulation, they are not readily subject to malfunction or inaccurate temperature measurements. Carefully calibrated to meet international standards, MI cables provide accurate and precise temperature measurement over long duty cycles with little or no loss of accuracy.

Molten Metal

Since the thermocouple probes are protected from contact with other electrically active wires by the insulation, they are not readily subject to malfunction or inaccurate temperature measurements. Carefully calibrated to meet international standards, MI cables provide accurate and precise temperature measurement over long duty cycles with little or no loss of accuracy.

Because of the mineral insulation, MI cables can operate in high-temperature conditions with no loss of accuracy. This makes them ideal in kilns, firing ceramics or heat treating metals or in any high-temperature process. MI cables retain their accuracy even during and after exposure to high temperatures, so they are ideal as a thermocouple probe in these operations. In addition, for industries such as medical devices or aerospace where safety standards are strictly enforced, process deviations could result in life-threatening quality issues. mineral insulated cables are carefully calibrated and verified using NIST standards at Omega against known temperatures or certified thermometers. NIST traceable calibration ensures temperature accuracy under actual operating conditions and provides documentation of their original accuracy. To remain NIST certified, the chain of verification must be intact and the thermocouples must be recalibrated as part of a well-documented and executed quality management system.