A stepper motor is a brushless, synchronous electric motor that converts digital pulses into mechanical shaft rotation. Every revolution of the stepper motor is divided into a discrete number of steps, in many cases 200 steps, and the motor must be sent a separate pulse for each step. The stepper motor can only take one step at a time and each step is the same size. Since each pulse causes the motor to rotate a precise angle, typically 1.8°, the motor's position can be controlled without any feedback mechanism. As the digital pulses increase in frequency, the step movement changes into continuous rotation, with the speed of rotation directly proportional to the frequency of the pulses. Step motors are used every day in both industrial and commercial applications because of their low cost, high reliability, high torque at low speeds and a simple, rugged construction that operates in almost any environment.

Stepper Motor Advantages

Converting a non-linear input signal to a linear output signal. This is common for thermocouple signals.

The rotation angle of the motor is proportional to the input pulse.

The motor has full torque at standstill (if the windings are energized).

Precise positioning and repeatability of movement since good stepper motors have an accuracy of 3 to 5% of a step and this error is non-cumulative from one step to the next.

Excellent response to starting/stopping/reversing.

Very reliable since there are no contact brushes in the motor. Therefore the life of the step motor is simply dependent on the life of the bearing.

The stepper motors response to digital input pulses provides open-loop control, making the motor simpler and less costly to control.

It is possible to achieve very low speed synchronous rotation with a load that is directly coupled to the shaft.

A wide range of rotational speeds can be realized as the speed is proportional to the frequency of the input pulses.

Types of Step Motors

There are three basic types of step motors: variable reluctance, permanent magnet, and hybrid. This discussion will concentrate on the hybrid motor, since these step motors combine the best characteristics of the variable reluctance and permanent magnet motors. They are constructed with multi-toothed stator poles and a permanent magnet rotor. Standard hybrid motors have 200 rotor teeth and rotate at 1.8º step angles. Because they exhibit high static and dynamic torque and run at very high step rates, hybrid step motors are used in a wide variety of commercial applications including computer disk drives, printers/plotters, and CD players. Some industrial and scientific applications of stepper motors include robotics, machine tools, pick and place machines, automated wire cutting and wire bonding machines, and even precise fluid control devices.

Step Modes

Stepper motor "step modes" include Full, Half and Microstep. The type of step mode output of any stepper motor is dependent on the design of the driver. OMEGA offers stepper motor drives with switch selectable full and half step modes, as well as microstepping drives with either switch-selectable or software-selectable resolutions.

FULL STEP

Standard hybrid stepping motors have 200 rotor teeth, or 200 full steps per revolution of the motor shaft. Dividing the 200 steps into the 360° of rotation equals a 1.8° full step angle. Normally, full step mode is achieved by energizing both windings while reversing the current alternately. Essentially one digital pulse from the driver is equivalent to one step.

HALF STEP

Half step simply means that the step motor is rotating at 400 steps per revolution. In this mode, one winding is energized and then two windings are energized alternately, causing the rotor to rotate at half the distance, or 0.9°. Although it provides approximately 30% less torque, half-step mode produces a smoother motion than full-step mode.

MICROSTEP

Microstepping is a relatively new stepper motor technology that controls the current in the motor winding to a degree that further subdivides the number of positions between poles. OMEGA microstepping drives are capable of dividing a full step (1.8°) into 256 microsteps, resulting in 51,200 steps per revolution (.007°/step). Microstepping is typically used in applications that require accurate positioning and smoother motion over a wide range of speeds. Like the half-step mode, microstepping provides approximately 30% less torque than full-step mode.

Linear Motion Control

The rotary motion of a stepper motor can be converted to linear motion using a lead screw/worm gear drive system. The lead, or pitch, of the lead screw is the linear distance traveled for one revolution of the screw. If the lead is equal to one inch per revolution, and there are 200 full steps per revolution, then the resolution of the lead screw system is 0.005 inches per step. Even finer resolution is possible by using the step motor/drive system in microstepping mode.

Series vs. Parallel Connection There are two ways to connect a stepper motor, in series or in parallel. A series connection provides a high inductance and therefore greater torque at low speeds. A parallel connection will lower the inductance which results in increased torque at faster speeds.

Driver Technology Overview

The stepper motor driver receives step and direction signals from the indexer or control system and converts them into electrical signals to run the step motor. One pulse is required for every step of the motor shaft. In full step mode, with a standard 200-step motor, 200 step pulses are required to complete one revolution. The speed of rotation is directly proportional to the pulse frequency. Some drivers have an on-board oscillator which allows the use of an external analog signal or joystick to set the motor speed.

Speed and torque performance of the step motor is based on the flow of current from the driver to the motor winding. The factor that inhibits the flow, or limits the time it takes for the current to energize the winding, is known as inductance. The effects of inductance, most types of driver circuits are designed to supply a greater amount of voltage than the motor's rated voltage. The higher the output voltage from the driver, the higher the level of torque vs. speed. Generally, the driver output voltage (bus voltage) should be rated at 5 to 20 times higher than the motor voltage rating. In order to protect the motor from being damaged, the step motor drive should be current-limited to the step motor current rating.

Indexer Overview

The indexer, or controller, provides step and direction outputs to the driver. Most applications require that the indexer manage other control functions as well, including acceleration, deceleration, steps per second and distance. The indexer can also interface to and control many other external signals.

Communication to the indexer is through an RS-232 serial port and in some cases an RS485 port. In either case, the indexer is capable of receiving high-level commands from a host computer and generating the necessary step and direction pulses to the driver.

The indexer includes auxiliary I/O for monitoring inputs from external sources such as a Go, Jog, Home or Limit switch. It can also initiate other machine functions through the I/O output pins.

Stand-Alone Operation

In a stand-alone mode the indexer can operate independent of the host computer. Once downloaded to the non-volatile memory, motion programs can be initiated from various types of operator interfaces, such as a keypad or touchscreen, or from a switch through the auxiliary I/O inputs. A stand-alone stepper motor control system is often packaged with a driver and power supply and optional encoder feedback for "closed loop" applications that require stall detection and exact motor position compensation.

Multi-Axis Control

such cases a multi-axis control system is available. A HUB 444 networking hub, for example, may have up to four stepper drives connected to it, with each drive connected to a separate stepper motor. The networking hub provides coordinated movement for applications requiring a high degree of synchronization, such as circular or linear interpolation.

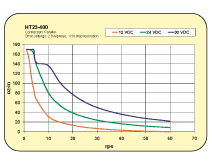

Choosing a Stepper Motor and Drive

The choice of a step motor depends on the application's torque and speed requirements. Use the motor's torque-speed curve (found in each drive's specifications) to select a motor that will do the job. Every stepper drive in the OMEGA line shows the torque-speed curves for that drive's recommended motors. If your torque and speed requirements can be met by multiple step motors, choose a drive based upon the needs of your motion system- step/direction, stand-alone programmable, analog inputs, microstepping- then choose one of the recommended motors for that drive. The recommended motor list is based on extensive testing by the manufacturer to ensure optimal performance of the step motor and drive combination.

Choose the right stepper motor for your application

Step and Direction

These step motor drives accept step pulses and direction/enable signals from a controller, such as a PLC or PC. Each step pulse causes the motor to rotate a precise angle, with the frequency of the pulses determining the speed of rotation. The direction signal determines the direction of rotation (CW or CCW), while the enable signal turns the motor on or off.

Oscillator

Step motor drives with a built-in digital oscillator accept an analog input or joystick for speed control. These systems are generally used in applications requiring continuous motion rather than position control, such as mixers, blenders, and dispensers.

Stand-Alone Programmable

All of these stepper drives can be programmed for stand-alone operation; the motion control program is created with a simple drag-and-drop high-level software interface (included free), then downloaded and executed upon power-up. The motion control program typically waits for an input such as a switch closure or button press before executing the programmed motion.

High Performance Stepper Motors

These step motor drives offer advanced features such as self-test diagnostics, fault protection, auto-tuning, torque ripple smoothing, command signal smoothing, and anti-resonance algorithms. Some drives are stand-alone programmable, while others offer step/direction and analog inputs. High-performance drives will provide the best possible performance for your motion control system.