Polyimide heaters are flexible, durable, and efficient heating elements made from polyimide, a high-performance polymer material known for its excellent thermal, electrical, and chemical resistance properties.

Polyimide heaters provide the thinnest profile of all flexible heaters, while offering precise heat distribution and excellent tensile strength. They work well in extreme heat environments or small spaces and are commonly used in applications where space is limited – or where the heater needs to conform for irregular shapes or surfaces.

Key Characteristics

- Material:Polyimide is a high-temperature-resistant material that can withstand a wide range of temperatures, typically up to 250°C (482°F), and in some cases, even higher.

- Flexibility:Polyimide heaters are thin and flexible, allowing them to be bent or shaped to fit specific applications. This makes them ideal for use in confined or intricate spaces.

- Efficient Heat Distribution:Polyimide heaters provide uniform heat distribution across the surface, which makes them effective for precise temperature control.

- Chemical Resistance:The material resists various chemicals, oils, and solvents, which enhances the durability of the heater in harsh environments.

- Lightweight:These heaters are lightweight, which is beneficial for portable or lightweight devices.

- Thin Profile:Their thin profile (typically just a few millimeters thick) allows them to be integrated into various compact applications without taking up much space.

How do Polyimide Heaters Work?

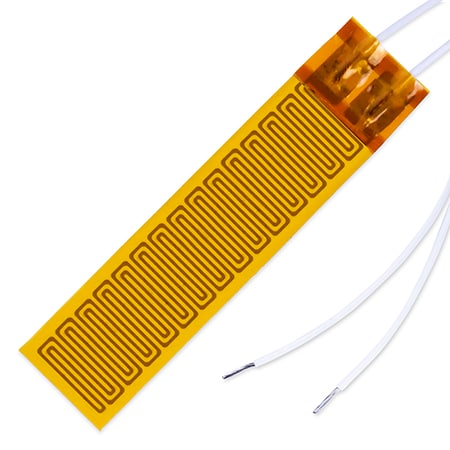

Polyimide heaters work through the principle of resistive heating, where an electric current flows through a metallic heating element embedded in a thin polyimide film. As the current passes through the resistive element (often made of materials like nichrome), it generates heat due to its resistance to the flow of electricity, in accordance with Joule's law (P = I²R). The polyimide film serves both as an insulating base and as a material that distributes heat efficiently across its surface. The flexibility of the polyimide allows the heater to conform to various shapes and sizes, ensuring uniform heat distribution.

These heaters often include temperature sensors such as thermistors or RTDs to regulate and maintain a precise temperature. The heat generated can be transferred to surrounding objects through conduction, convection, or radiation, depending on the application. Polyimide heaters are known for their quick response times, compact designs, and durability, as the material can withstand high temperatures, chemicals, and mechanical stress. Their thin profile and flexibility make them ideal for use in tight spaces or environments where traditional rigid heaters might not be practical.

How are Polyimide Heaters Constructed?

- Polyimide Film:This serves as the base material and provides the flexibility and durability of the heater. Polyimide is known for its high thermal stability and resistance to chemicals, making it ideal for high-temperature environments.

- Heating Element: This is usually made of a thin layer of a metal alloy, such as nichrome (nickel-chromium), copper, or stainless steel. The heating element is patterned on the polyimide film in a way that allows the electrical current to flow through it, creating heat through resistive heating.

- Electrical Connections:The heater has terminals or leads that are attached to the ends of the heating element, allowing electricity to flow into the circuit. These are typically insulated to ensure safe operation.

Polyimide Heater Applications

Polyimide heaters are widely used across various industries due to their flexibility, durability, and precise heating capabilities. In electronics, they are employed to heat components in devices such as smartphones, laptops, and circuit boards.

In the aerospace industry, polyimide heaters play a crucial role in thermal control for instruments, satellites, and other essential systems used in space exploration, ensuring optimal temperature management in harsh environments.

In medical applications, polyimide heaters are commonly found in devices like incubators, blood warmers, and medical imaging systems, where accurate and safe heating is vital. The automotive industry also benefits from polyimide heaters, which are used in applications like heated seats, defrosters, and other systems where both compactness and reliable temperature control are required. These diverse applications highlight the versatility and importance of polyimide heaters in modern technology.