A Sanitary Sensor is a device which measures temperature, flow or pressure in an environment where products will be for human consumption.

In typical industrial applications, measurements of parameters such as temperature, flow, level, or pressure simply involve finding a device with the right specifications that is designed to provide reasonable durability and a satisfactory life in its operating environment. The measurement range needed and special environmental concerns, such as exposure to corrosive liquids or gases help narrow down the choices.

This is where 3-A sanitary standards come in. Unlike other types of standards, equipment displaying the 3-A Symbol has been shown to meet certain material, design and fabrication standards for cleanability and inspection.

Learn more about Sanitary Sensors

Preventing Contamination

The sidebar shows just a few of the typical applications where sanitary sensors must be used in order to protect the end products from inadvertent contamination. As you can see, the range of products requiring sanitary processing is extensive, and we all use these products and benefit from the use of sanitary sensing devices. From a safety standpoint, besides functionality a key focus of sanitary sensor design is on maintaining sterility and avoiding contamination of the product. There are three key factors that contribute to meeting this goal; the exposed surface of the sensor, the mechanical design and installation methodology, and the ease which with the sensor can be thoroughly cleaned. Let's consider each of these issues.

Food Products: Syrup, jam, sauces, soups, oils

Beverages: Soda, fruit juice, beer, water

Pharmaceutical Products: Medication, ointments, solutions

Cosmetics: Creams, lotions, lipstick

The Sensor Surface

Any consumable or applied product for which contamination must be avoided. The 3-A sanitary standards specify the required properties of a sensor surface in contact with the product. Contamination can occur from the process material clinging to the surface of the sensor and serving as a breeding ground for microbes. Consequently, contact surfaces must be very smooth, non-porous, and easily cleaned. In addition, it must be non-reactive and non-contaminating. Corrosion resistance is also very important since corrosion can lead to pitting where contamination can become imbedded.

Design And Installation

The mechanical configuration of the sensing device where it is exposed to the product being processed can introduce opportunities for contamination. To meet the 3-A standards, the sensor must be made from corrosion resistant materials, assembled using accepted processes and be designed with features that would not trap debris and encourage microbe growth. At the installation location, it is desirable to avoid or minimize stagnant zones in the fluid conduits where the product can be trapped and remain after the system is drained. In the case of products that are sticky or have high viscosity, these areas can be difficult to clean. Conduit offsets and T-connections necessary to install a sensor can lead to such stagnate zones.

Cleanability

For process efficiency, it is best to be able to wash out the system between runs without having to remove the sensors. This is called "cleaning in place" or CIP. Sensors that require manual cleaning and inspection add to turnaround time between batches and increase labor costs. This increased handling can also lead to increased risk of contamination.

Although we typically do not give it much thought, everyone who eats, drinks, takes medication or uses cosmetics is a beneficiary of the specialized sensing and measurement devices used in manufacturing these products. By combining our experience in sensor design & development, with new technology and industry leading product availability and support, OMEGA can be your source for leading edge sanitary sensing products that ensure the best possible outcome in any of these critical and important processes.

Choose the right sanitary sensor for your application

Below is a review of the most common types of sanitary sensors used for temperature, pressure, flow, and level control applications. OMEGA™ provides a comprehensive line of 3-A sanitary sensors, and we will use examples from our various product lines for illustrative purposes. OMEGA also offers some unique products for wireless connectivity which can greatly simplify sensor installation and maintenance.

Temperature Sensors

One of the simplest and least expensive 3-A temperature measurement devices is the dial thermometer. However, these sensors are limited to situations where manual monitoring is used and accuracy requirements are not too stringent. The most accurate and most popular device for process temperature control is the RTD (resistance temperature detector, model PRS-3-100-A-H-0600-D1-NB9W shown left). An RTD that meets 3-A sanitary standards can be provided in the form of a probe for direct immersion (and faster response time) or can be enclosed in a thermowell for mechanical protection and ease of replacement. Direct immersion RTD sensors are provided with straight or stepped probe designs depending on response time and process flow conditions. The wetted surfaces are 316L stainless steel, and are highly polished to meet 3-A requirements. These sensors are also supplied with traditional connection heads, M12 connections, integral extension cables or wireless features for ease of installation.

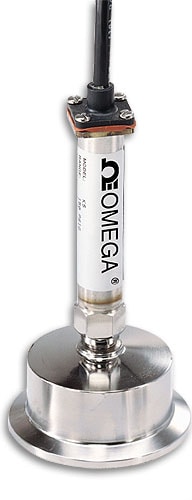

Pressure Transmitters

The item shown to the left is a 3-A sanitary pressure transducer. This device is typically used in dairy, food processing, pharmaceutical, and biotech applications. Construction is all stainless steel with an electro-polished finish. This unit is designed for clean-in-place operation. This sensor utilizes thin-film technology which is known for reliability and accuracy. It is calibrated to NIST standards. The low response time of 5 msec ensures tight process control. The reading is delivered via a 1 to 5 Vdc output signal or a 4 to 20 mA current loop.

Turbine Flowmeters

Sanitary turbine flowmeters, such as the FTB400A, are used in processing liquids and beverages. They are also found in applications requiring pasteurization and can be used for thicker materials such as ketchup and chocolate. Units are available in sizes ranging from ¼ to 3" in diameter. This type of sensor covers flow ranges from a fraction of a gallon per minute (GPM) up to hundreds of GPM. The design of the flowmeter and materials of construction are suitable for cleaning in place (CIP).

Flow Transmitters and Switches

The Model FSW-9000 transmitter/switch monitors the flow velocity of the product based on the principle of thermal dispersion between heated and unheated RTDs immersed in the product. It generates an analog output signal corresponding to the flow rate and includes a set point feature which can signal a process controller or operator when a specified flow is achieved. If an actual flow measurement is not required, a simpler flow switch can be used to signal when the flow rate set point is reached.

Level Monitoring

In processes using a vat or other large container, the fill level can be accurately measured with non-contact sensors. These replace capacitance or float-type devices which require immersion in the product. The LVU1500, to the left, shows an ultrasonic level transmitter. This unit emits ultrasonic pulses which are reflected at the air/liquid interface to detect and measure the fill level. For situations where foam, dust, or vapors interfere with ultrasonic measurements, a radar-based level transmitter such as the LVRD500 may be used.

Wireless Connectivity Options

A further refinement to sanitary sensor applications is through the use of wireless technology to transmit measurement data. Here OMEGA has a comprehensive range of products that simplify installation and maintenance, as well as add analytical and control software to improve process control and monitoring. The UWRTD-NB9W is an RTD-to-wireless unit that transmits measurements to a matching receiver that can handle up to 48 channels. Matching software logs data and provides process control signals.