An Introduction to Omega's Calibration Solutions

Calibration is crucial in industrial manufacturing because it ensures the accuracy and reliability of measurement instruments and equipment used in production processes. With proper calibration, manufacturing professionals can verify performance against recognized standards and initiate adjustments, if necessary.

What is Calibration?

Calibration is the comparison of a measurement value from the device under calibration with that of a known, traceable calibration reference – typically a device that is more accurate than the unit being calibrated and with accuracy traceable to a recognized standard.

If discrepancies between the instrument’s readings and the reference standards are detected during calibration, adjustments are made to the instrument to align its measurements with the known values. This adjustment may involve tweaking settings, calibrating sensors, or modifying the instrument’s internal components.

Why is Periodic Calibration Important?

The accuracy of process measurement devices can drift over time when they are subjected to everyday wear and tear – such as:

- Harsh or Abrasive Media

- Shock or Vibration

- Other Environmental Conditions

Sensor drift can occur at a rate that is unnoticeable to the average user – eventually leading to measurement errors and even safety issues. Ultimately, unchecked sensor drift will undoubtedly result in expensive repairs and costly downtime. Or worse.

That’s why maintaining devices at their highest level of accuracy through periodic calibration is one of the most important parts of any process maintenance program.

Who Should Calibrate YOUR Device?

Devices can either be calibrated at the factory where the device was manufactured or out in the field where the device is being used.

Factory calibration is when a device is calibrated by the manufacturer and often a certificate of calibration – specifying the device’s accuracy and adherence to standards – is provided. Having a device calibrated by the manufacturer is best when a user is intended on quickly utilizing a device.

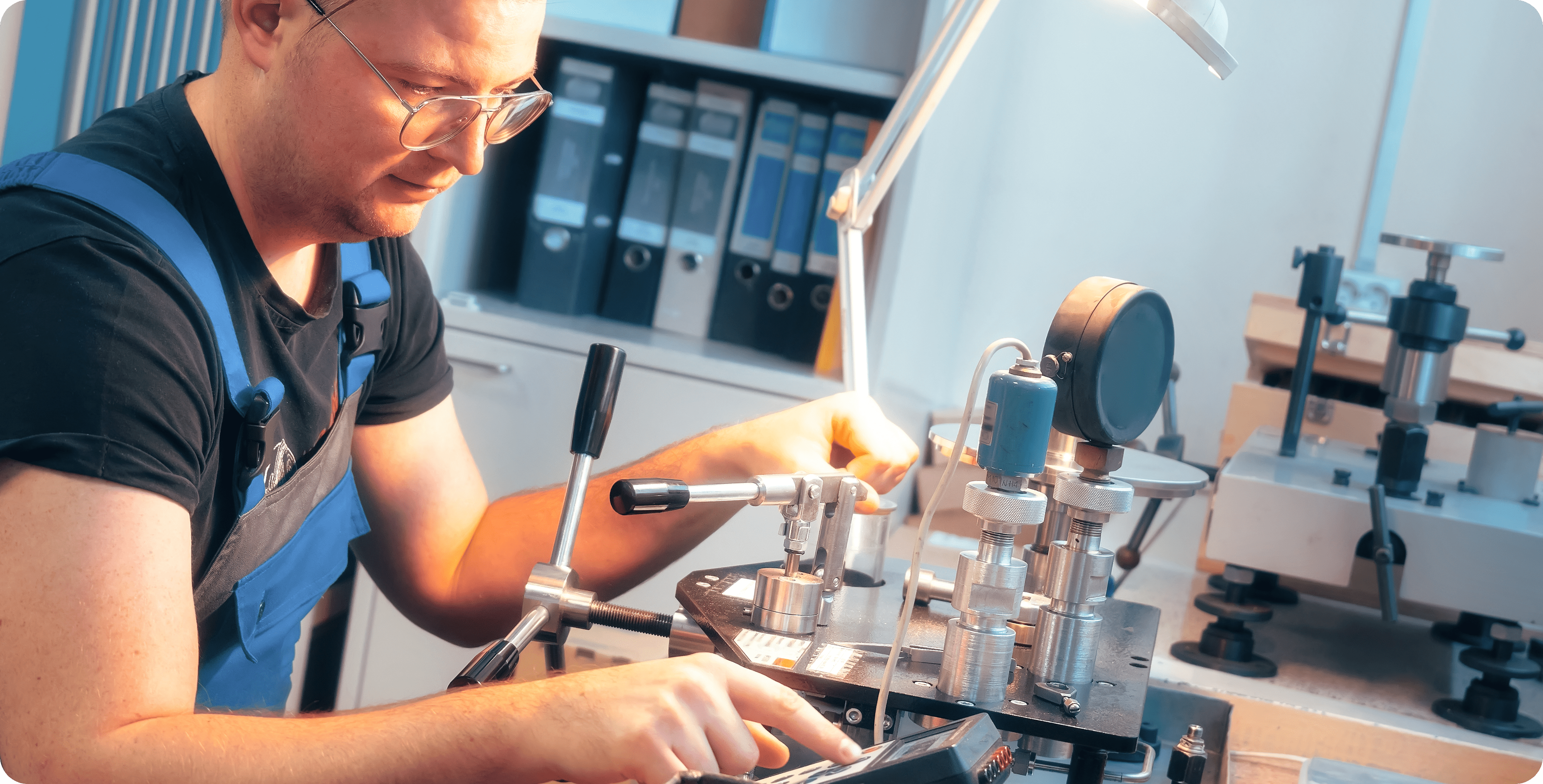

Field calibration, on the other hand, is when calibration occurs on-site at the location where the device is intended to be used. Often, field calibration is completed by a trained technician. A benefit of field calibration is that it allows for fine-tuned calibration to the environmental parameters required for the device to work properly within a specific system. In addition, if the device is required to communicate with other devices in an integrated system, field calibration can adjust accordingly.

For results you can trust, calibration should be conducted by a lab that is certified under ISO standards. This provides a calibration that is traceable to the US National Institute of Standards and Technology (NIST). Traceable calibration provides a foundation for accurate, reliable, and compliant measurements – a major contributor to quality, safety, and cost-effective best practices.

Omega – Decades of Calibration Experience

Omega is a leading marketer and manufacturer of process measurement technologies, and we feature unparalleled calibration services. Our in-house calibration team feature highly skilled technicians experienced in all forms of calibration. We offer a broad selection of primary and secondary NIST traceable calibration standards for measurement and control products of all kinds, including:

Temperature Calibration

Omega has a state-of-the-art Temperature Calibration Laboratory, which features a sophisticated HVAC system used to control both the temperature and humidity to precise limits. This ensures the best accuracy from the high precision measurement equipment used inside. The lab is built as a room within a room – eliminating temperature fluctuations from exterior walls – and all high-temperature furnaces are located outside the lab – ensuring temperature and humidity stability inside the lab.

All said and done, Omega’s Temperature Calibration Lab has the resources to test from -112 °F (-80 °C) to 2372 °F (1300 °C).

Omega uses a variety of fluid baths, furnaces, and calibrators to perform temperature calibrations over a wide temperature range. Each heat source is outfitted with an independent NIST traceable standard. The most accurate equipment is selected for each calibration situation to provide the lowest temperature measurement uncertainties.

Omega’s Five Levels of Temperature Calibration

CAL-1

This level documents that the products you buy comply with Omega’s specifications. This calibration provides additional assurance that what you are buying is exactly what has been specified in the product specifications.

CAL-2

This level documents not only that the equipment you buy meets the published specifications, but also that calibration and testing were performed using NIST-traceable equipment.

CAL-3

This level provides temperature deviation data at Omega’s pre-determined temperature points as well as a list of all test equipment used with calibrations traceable to NIST. Tis calibration is performed in accordance with ISO-10012-1 and ANSI/NICL-Z540-1-1994 requirements. This certificate is available for most Omega manufactured Thermocouple, RTD, and Thermistor temperature measurement probes.

CAL-4

This level is similar to the previous level, except that specific temperature points are chosen by the customer. This calibration is also performed in accordance with ISO-10012-1 and ANS/NCSL-Z540-1-1994 requirements. This certificate is available for most Omega manufactured Thermocouple, RTD, and Thermistor temperature measurement probes.

CAL-5

This level documents that a Thermocouple probe was made from a spool of Omega’s MI thermocouple wire and checked at various temperatures. This certificate is NOT NIST traceable.

Omega Calibration services offer the following:

- All NIST Traceable

- All Meet or Exceed ISO 10012-1, ANSI/NCL Z540-1-1994 Standards

- Lab is ISO 9000-2015 Compliant

- Low Measurement Uncertainties

- Individual Probe Calibration

- Instrument Calibration

- System Calibration (Probe Connected to Instrument)

For more information on Omega’s NIST Traceable Calibration Services for Measurement and Control Products, please click here.