Although accurate, load cells are prone to deterioration from continuous usage and environmental conditions – which can lead to inaccurate measurements. Therefore, it is important to ensure that a load cell is working properly.

Although accurate, load cells are prone to deterioration from continuous usage and environmental conditions – which can lead to inaccurate measurements. Therefore, it is important to ensure that a load cell is working properly.

To assess the status of a load cell system:

Check that the weight indication returns to zero when the system gets unloaded Check that they system is able to indicate the same weight even if the location of the load changes (uneven loading).

If a load cell system is not showing these signs, it is time to re-calibrate the load cells. Several tests are available to check to see if a load cell is causing problems. These include:

- Mechanical inspection

- Zero balance test

- Bridge resistance test

- Resistance to ground test

What Does ‘Calibration’ Mean?

Calibration can be defined as the comparison between the results of a sensor’s measurement and a calibration standard so that necessary adjustments can be made to minimize any deviations or errors.

Calibration can be defined as the comparison between the results of a sensor’s measurement and a calibration standard so that necessary adjustments can be made to minimize any deviations or errors.

Calibration service helps ensure that instruments and systems provide accurate measurements and consistent results, enables reliable data analysis, precise measurements, and adherence to industry standards, and is crucial in various fields, including industrial processing and manufacturing.

It is important to perform frequent calibrations and regular calibrations at regular intervals to maintain accuracy and consistency in equipment and devices.

Load Cell Calibration Procedure

Before load cell calibration, the mechanical system should be examined, and the load cell installation checked for load cell cable and/or coil excess – which would then need to be inspected and protected. The load cell should be equally distributed among multiple load cells of multiple load cell installations. If the differ by more than 10%, the load should be rebalanced and adjusted with shims. When installing, calibrating, or removing a cell, the vessel should be lifted without unloading or overloading the other cells. The design of the system should provide for jacking and the horizontal removal of the cell. It is essential to note that dummy load cells should be used in place of operational ones until all construction and welding are completed.The calibration of the vessel requires hangers or shelves to support the calibration weights. For an ASME vessel, they must be added when the vessel is fabricated. Calibration to an accuracy of 0.25% full scale or better is usually performed with dead weights and is the only calibration method recognized by weights and measures agencies.

All load cell calibration needs to be done with the load cell mounted into the system, and all load cell calibration experiments start by zeroing the system.

Calibration Methods

Deadweight Calibration

Deadweight calibration is a method in which the vessel is evenly loaded to 10% of the live load capacity using standard weights. The weight indication is recorded, and the weights are removed. Next, process material is added to the vessel until the weight indicator registers the same (10%) weight as it did with the calibration weights. Now the calibration weights are loaded on the vessel again and the reading (now about 20%) is recorded. These steps are repeated until 100% of capacity is reached.

Deadweight calibration is a method in which the vessel is evenly loaded to 10% of the live load capacity using standard weights. The weight indication is recorded, and the weights are removed. Next, process material is added to the vessel until the weight indicator registers the same (10%) weight as it did with the calibration weights. Now the calibration weights are loaded on the vessel again and the reading (now about 20%) is recorded. These steps are repeated until 100% of capacity is reached.

Live Weight Calibration

Live weight calibration is a novel and faster method, which uses pre-weighted people as calibration weights instead of calibrated dummy weights. The procedure is identical to deadweight calibration. This method should not be used if there is a risk of injury.Material Transfer

The ‘material transfer’ method of load cell calibration uses some other scale to verify weight. This method is limited by the accuracy of the reference scale and risks some error due to possible loss of material in transfer.Master Cell

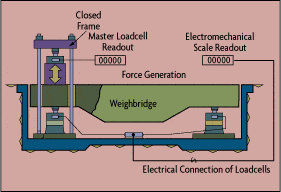

A master cell can also be used for calibration – as long as the master is about three times more accurate than the accuracy expected from the calibrated system. The load cells calibration process involves incremental loading and the evaluation at each step of the output signals of both the calibrated weighbridge and of the master load cell (Figure 1). The number of divisions used and the method of applying the force (hydraulic or servomotor) is up to the user. 2Load Cell Issues

If a load cell system is causing problems, load cell troubleshooting is explained here.- What is a Load Cell?

- Types of Load Cells

- Selecting a Load Cell

- FAQ

- Installing a Load Cell

- How to Wire a Load Cell?

- Troubleshooting

- Amplifiers for Load Cells

- Data Loggers for Load Cells

- Load Cell Meter

- Load Cell Controller

- Signal Conditioners

- Weighing Trucks, Trains, and Aircraft

- Dynamic Load Measurement

- Testing Load Tolerance in Cables

- Critical Component in X-ray Laser