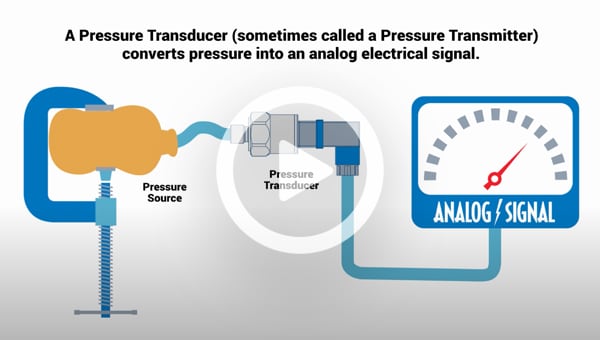

A pressure transducer, often called a pressure transmitter, is an electromechanical device designed to measure pressure with a high degree of accuracy. Pressure transducers sense applied pressure and output an electrical signal by using a combination of mechanical and electical compntents. The most common transducer outputs are voltage and milliamps.

Pressure Transducers Based On Measured Pressure

Absolute Pressure

Absolute pressure transducers measure the pressure relative to a perfect vacuum, using absolute zero as a reference point. An example is a barometric pressure transducer. These also include sealed gauge, where the signal has been offset to match the gauge pressure at the time of construction.

Gauge Pressure

Gauge pressure transducers measure the pressure relative to local atmospheric pressure. An example is a tire pressure sensor. Another example would be a vacuum sensor, whose signals are reversed so that they signal positive when the measured pressure is below atmospheric pressure.

Differential Pressure

Differential pressure transducers measure the difference between two applied pressures. These transducers generally have a high and a low pressure port. One common instance of differntial pressure would be filter monitoring. As the filter gets clogged, the differential pressure increases.

The Electrical Output of Pressure Transducers

Pressure transducers are generally available with three types of electrical output: millivolt, amplified voltage, and 4-20mA. Below is a summary of the outputs and when they are best used.

Millivot Output Pressure Transducers

Transducers with millivolt output are normally the most economical pressure transducers. The output of a millivolt transducer is nominally around 30mV. The actual output is directly proportional to the pressure transducer input power or excitation. If the excitation fluctuates, the output will change also. Because of this dependence on the excitation level, regulated power supplies are suggested for use with millivot transducers. Since the output signal is so low, the transducer should not be located in an electrically noisy environment. The distances between the transducer and the readout instrument should also be kept relatively short.

Voltage Output Pressure Transducers

Voltage output transducers include integral signal conditioning which provide a much higher output than a millivolt transducer. The output is normally 0-5Vdc or 0-10Vdc. Although model specific, the output of the transducer is not normally a direct function of excitation. This means unregulated power supplies are often sufficient as long as they all within a specified power range. Because they have a higher level output, these transducers are not as susceptible to electrical noise as millivolt transducers and can therefore be used in much more industiral environments.

Current Output Pressure Transducers

These types of transducers are also known as pressure transmitters. Since a 4-20mA signal is least affected by electrical noise and resistance in the signal wires, these transducers are best used when the signal must be transmitted long distances. Pressure transducers are generally available with three types of electrical output; millivolt, amplified voltage and 4-20mA. In this article how to wire different types of pressure transducers based on its output is explained.

Afterwards, it is necessary to convert an electric output into an engineering unit such as PSI or bars.

Below is a summary of the outputs and when they are best used.

Millivolt Output Pressure Transducers

Transducers with millivolt output are normally the most economical pressure transducers. The output of the millivolt transducer is nominally around 30mV. The actual output is directly proportional to the pressure transducer input power or excitation.

If the excitation fluctuates, the output will change also. Because of this dependence on the excitation level, regulated power supplies are suggested for use with millivolt transducers. Because the output signal is so low, the transducer should not be located in an electrically noisy environment.

The distances between the transducer and the readout instrument should also be kept relatively short.

Voltage Output Pressure Transducers

Voltage output transducers include integral signal conditioning which provide a much higher output than a millivolt transducer. The output is normally 0-5Vdc or 0-10Vdc.

Although model specific, the output of the transducer is not normally a direct function of excitation. This means unregulated power supplies are often sufficient as long as they fall within a specified power range.

Because they have a higher level output these transducers are not as susceptible to electrical noise as millivolt transducers and can therefore be used in much more industrial environments.

4-20 mA Output Pressure Transducers

These types of transducers are also known as pressure transmitters. Since a 4-20mA signal is least affected by electrical noise and resistance in the signal wires, these transducers are best used when the signal must be transmitted long distances.

It is not uncommon to use these transducers in applications where the lead wire must be 1000 feet or more.

Choose the right pressure transducer for your application

PC Board Mountable Pressure Transducers

PC board mountable pressure transducers are generally compact economical pressure transducers designed to mount on an electrical PC board and be integrated into other products.

General Purpose Transducers

General purpose pressure transducers are the most common since they are designed to fit the broadest set of applications.

Heavy Duty/Industrial Pressure Transducers

Heavy Duty/Industrial Pressure transducers feature a much more rugged enclosure than other transducers. They are designed to accommodate heavy industrial environments. They also often feature a scalable 4-20mA output that provides much greater immunity to electrical noise which is not uncommon in industrial environments.

High Stability/High Accuracy Pressure Transducers

Most pressure transducers feature an accuracy of 0.25% of full scale or higher. High stability and high accuracy pressure transducers can offer errors as low as 0.05% of full scale, depending on model. Although more expensive than general purpose transducers, they may be the only option if high precision is required.

Flush Diaphragm Pressure Transducers

With flush diaphragm pressure transducers, the diaphragm is flush to the process. This eliminates a cavity above the diaphragm that could collect fluid matter from the process. In certain applications, this may be very undesirable. Those applications include monitoring the pressure of foods or liquids that have very high viscosity.

Special Purpose Transducers

OMEGA offers a variety of pressure transducers with special features. These include pressure transducers designed for pressure measurement in very high or low temperatures, submersible pressure transducers, barometric pressure transducers and pressure transducers with digital communications output or wireless outputs.