Selecting the proper cable family according to the process conditions is necessary to get desired temperature controls within the pipes.

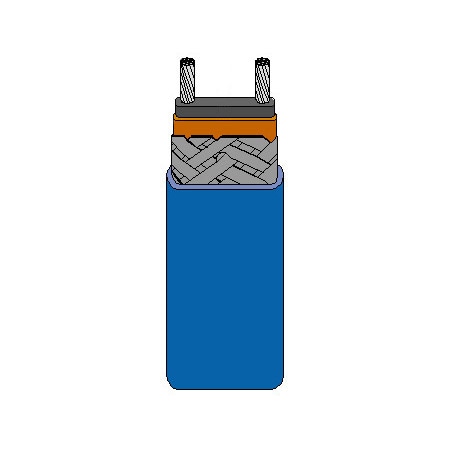

The modern heat traces use polymer-based cables. These cables can adjust the current flow according to the ambient temperatures. For example, if the ambient temperature is low, more current will pass through the cables, resulting in more heat.

Heat Trace cable can be lower in price if they are not properly certified for hazardous areas. Be mindful when selecting the right cable that your choice is based on its rating.

The following are factors that you need to consider when selecting the heat trace cable for your application.

- Maximum maintenance temperature

- Maintenance temperature

- Maximum exposure temperature

- Thermal output rating

You should also consider selecting the cable with a proper jacket material that will offer the desired level of protection against corrosion and mechanical wear and tear. Most heat trace cable manufacturers provide detailed literature with comparison tables so that you can match the cable with your system requirements.

Once you’ve identified the perfect cable for your heat trace system, you’ll also need to calculate the total cable length required. Make sure that you also consider the inline equipment such as valves, flanges, and pipe support when you measure the total pipe length as these will require additional heat tracing.

Finally, choose the right thermostat control device and other cable connection accessories according to your application. Contact your heat trace system manufacturer to get comprehensive design guides with accurate specifications and other design data.

Things You Should Consider During Heat Trace Installation

Heat trace installation requires skill and planning. Here are some essential tips you should consider when laying heat traces.

- Study the layout of the pipes or the vessel to get maximum efficiency and coverage. Without a route map, the chances of hot or cold spot formation are going to be significant.

- Heat traces carry electric current through them. Hence, all the conductive parts of the heat trace must be insulated. Take special care to seal the ends of the exposed cables.

- Sensors play an important part in keeping a check on the temperatures. Place the ambient temperature sensors in places that exhibit the coldest temperatures. Make sure that you install the sensors in the right area.

- Route the cables in a way so that it is easy to remove the valves when needed.