How a New Temperature Monitoring Technology is Quickly Rising to the Top in Food and Bev Manufacturing and Processing

People’s Choice: A Little Sensor Making Big Waves

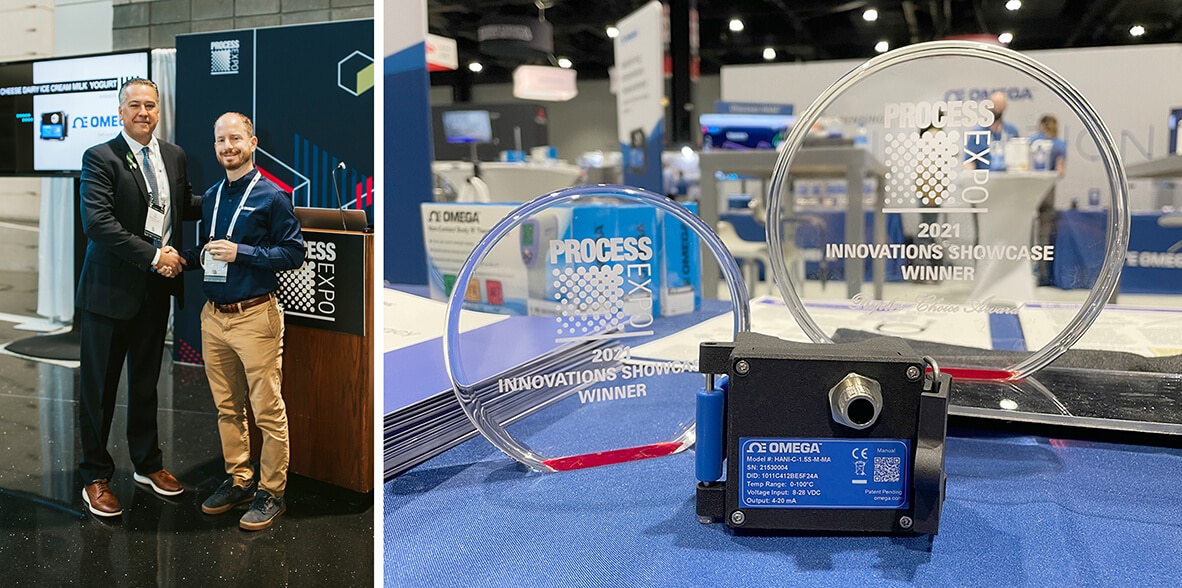

It was a good day for Omega at the 2021 Process Expo event. Our new HANITM temperature sensor was announced winner of the Cheese, Dairy, Ice Cream, Milk, and Yogurt category of the Innovations Showcase, a competition highlighting top technological innovations in processing and packaging for the Food and Beverage industry. A standout among an impressive selection of new products, the HANI sensor received quite a buzz from Food and Beverage professionals as well as some serious media attention on the show floor. And people were buying them – right there at the show. Then we got the news: HANI won the People’s Choice award as well. It really was a good day for Omega.

How does an unassuming little temperature sensor earn its way to best-in-show? To understand this, we need to first understand the problem at hand.

The Problem: Probes and Pipes

Until now, the only way Food and Beverage manufacturing professionals could obtain a fast and accurate temperature reading for product in the pipe was to put a temperature probe into the process line so it could make direct contact with that product. This means before a measurement can even be taken, you’d have to bring in contractors to cut, drill, and perform sanitary welds to install those sensors. And, as we all know all too well, bringing in contractors means shelling out money. On top of that, if your sensors are placed in non-ideal locations or you change pipe configuration, then you’re forced to shut everything down, sometimes for days, and do it again – followed by a sanitary clean.

Because the sensor touches the product, it adds risk of cross contamination – from things like pieces breaking or metal scraping off into the product. If the product has solids in it – like ice creams, yogurts, or soups – that solid product can build up on and around those invasive sensors as well as the tee fittings they’re housed in and interfere with readings (meaning inaccurate temperature measurements or extremely slow response times) and cause blockages, which requires production be shut down, pipes opened, and additional sanitary cleans initiated.

Speaking of sanitary cleans, manufacturers using product recovery (pigging) systems to reduce clean-in-place (CIP) costs and increase product yields must first remove those invasive sensors, so they don’t impede the travel of the pig through the pipe. And even with the sensors removed, the tee fittings required to accommodate those invasive sensors cannot be cleared by the pig – meaning product yields are ultimately limited. Plus, these tee fittings require additional time, water, chemical usage, and energy to the cleaning process. Ultimately, many of the benefits of using a pigging system are negated. You can almost see the dollars (and the frustration) pilling up.

Technology Breakthrough: High Accuracy, Non-Invasive (HANI)

Enter HANI sensors, which do what few thought was even possible: they measure, with very high accuracy, the temperature of moving process media inside a pipe without the use of an invasive temperature probe.

HANI sensors mount to the outside of a pipe and measure media inside the pipe, accurately, in seconds. There’s no need to cut, weld, drill, or shut down production to install or move a HANI sensor. In fact, you can install a HANI sensor without using a single tool. It doesn’t touch the product, so there’s no risk of cross contamination, and it can never clog a pipe, so it will never interfere with a CIP pigging system. That means less wasted product and higher production yields.

How It Works

“Installing or relocating an invasive in-pipe sensor can be an expensive, time-consuming process,” explains Ahmar Bajwa, Omega’s Director of Product Management. “With HANI sensors, customers don’t need to worry about immersion depth, material compatibility, corrosion, or contamination risks. And there’s no loss of performance, so it’s really a best-of-both-worlds-approach.”“Until the HANI was made available, I had no way to non-invasively measure temperature in a pipe accurately.” - Eric Anderson, Chief Brewing Officer & Co-Founder at Saucy Brew Works

“Take the Omega [HANI] sensor, set it on the pipe, wrap the strap around and clamp it on, and plug it in. Takes seconds versus days. The accuracy of the Omega sensor is just as good as – or faster – than the thermocouples we have in-line.” – Steve Baughman, Senior Maintenance Mechanic at Rutgers’ Food Innovation Center

From unboxing to measurement-ready, HANI sensors take about 10 seconds to install – just wrap the sensor strap around the desired pipe and pull the quick-latch mechanism, automatically setting the tension for the specified pipe diameter. (One of our brewery customers described it as “literally the easiest thing I’ve ever done.”) Once mounted, you can start getting high accurate, immersion-probe level temperature measurement. Electrically, there are three ways to connect: either via an analog system, USB cable connection, or wirelessly.

HANI is the only temperature sensor on the market today that uses a thin-film heat-flux sensor to assist in the temperature calculation. This, plus our proprietary algorithm, enables the Omega HANI sensor to offer accuracy (±0.9◦F) and response times (t63 = 5 sec) comparable to immersion RTD temperature sensors, making it the only non-invasive sensor on the market capable of doing so – and HANI is less expensive than other non-invasive temperature sensors.

Winning the People’s Choice award at this year’s Process Expo event truly is a testament to the significant impact HANI sensors are already having on the Food and Beverage industry. There is a growing consensus among Food and Bev professionals that HANI is a complete game changer – uniquely innovative technology that eliminates industry problems that have long been begrudgingly accepted as “necessary evils.”

From awards and accolades to raving reviews and the successful implementation in processing systems of all different kinds, HANI is proving to be the cream of the crop in new, innovative technology for the Food and Beverage industry.