Omega's HANI Temperature Sensor

Omega's HANI Temperature Sensor

In every stage of production – from initial processing to final delivery of product to customer – proper hygiene and sanitization practices are essential within the dairy industry. Exposure to unhygienic processing conditions can put dairy products at risk of contamination; microbes such as Salmonella, Campylobacter jejuni, Listeria monocyogenes, and Yersinia enterocolitica (just to name a few) can cause consumers serious ailments.

To uphold necessary hygiene standards in the processing of dairy products, systems managers and operators are well advised to utilize modern equipment – 3A certified where needed – as well as advanced monitoring measures. While in the past cleaning was done manually, it has become standard practice in the dairy industry to use automated Clean in Place (CIP) systems to clean and maintain processing equipment.

CIP system

CIP system

What is a CIP System?

CIP systems pump cleaning and sanitizing solutions through the process piping path of a dairy processing system – allowing for effective cleaning and sanitization of all internal surfaces of equipment without the need for disassembly. Automated CIP systems minimize mistakes caused by human error, reduce costly downtime, and increase product quality consistency.

While every CIP system is unique – elements, sequence, and duration vary based on each individual processing system – the basic CIP cleaning cycle consists of 5 steps:

- Pre-Rinse: De-ionized (DI) water that has been processed through reverse osmosis (RO) is run through the system to wet the interior and to remove remaining residue.

- Caustic Wash: Caustic soda (sodium hydroxide) – at a concentration range of 0.5-2.0% – is run through the system to soften fats. There is a target temperature range of 140°F – 185°F (60°C – 85°C).

- Intermediate Rinse: Fresh water is run through the system to flush out any remaining residual from the caustic wash.

- Final Rinse: Another run of DI, RO water.

- Sanitizing Rinse: Peracetic acid (PAA) is used to kill microorganisms before the system is used for its next production run.

- Product Recovery (or “Pigging”) Systems: A projectile is sent through the process system to push out residual product.

- Acid Washes: An acid (most commonly nitric acid) is run through the system to remove milk scale (also known as “milk stone”). There is a target temperature range of 130°F – 150°F (54.4°C – 65.5°C).

- Air Blows: CIP compatible air blows are used to remove moisture remaining in the system after the final rinse step.

CIP System Implementation Hurdles – Temperature Monitoring

While automated CIP systems are incredibly beneficial for any dairy production system, there are some inevitable hurdles when it comes to implementation.

One such problematic hurdle is obtaining the accurate temperature monitoring required for the CIP process to be effective. During the various stages of a CIP system, prior to being sent into the equipment, CIP cleaning agents need to be heated to the correct temperature range so that they can thoroughly clean the interior surfaces of dairy processing equipment. In addition, temperature of CIP cleaning agents is measured once again when they leave the equipment and enter the return line – this measurement is taken to ensure that the temperature threshold of the CIP cleaning agents was maintained while running through the equipment.

To obtain the accuracy necessary for effective CIP implementation, processing operators and managers in the dairy industry have long turned to invasive, immersion sensors, such as thermocouples and RTDs. However, these in-pipe temperature sensor probes – as well as their (often necessary) protective thermowells – create some major operational headaches.

These invasive sensor probes:

- Are difficult and time-consuming to install – requiring invasive installation measures, including cutting, drilling, and welding; all of which cause costly downtime.

- Can be limited in where they can be installed within the system – installation can be prohibited by challenges in the design and layout of the system. And once a sensor is installed in a particular location, it is difficult and time consuming to move the sensor to a different location within the system.

- Are prone to media buildup that can cause sensor drift – semi-solid media, which is common in the dairy industry, can cause particle build up around an in-pipe sensor probe or thermowell. This buildup can result in loss of accuracy.

- Present a serious contamination risk – the aforementioned media buildup can cause contamination of product which, as all dairy industry professionals know, is something to be avoided.

- Block the path of the ‘pig’ projectile in a pigging system – the in-pipe sensor probes that immersion temperature sensors require prevent the ‘pig’ projectile.

Immersion temperature sensors and their invasive, in-pipe sensor probes have long been tolerated in the dairy industry (and among many other industries) for use in the CIP process because of their high accuracy. There simply was no other option – and temperature monitoring is that important when it comes to cleaning and sanitizing equipment.

But now, with Omega’s new, award-winning HANI High-Accuracy, Non-Invasive Clamp Temperature Sensor, there is an option. HANI sensors, which use multiple sensors and a proprietary algorithm, are as accurate as invasive, immersion sensors, and, because they require no in-pipe sensor probe of any kind, are ideal for CIP temperature monitoring.

4 Ways HANI Sensors Improve CIP Implementation and Performance in Dairy Production:

1. HANI Sensors Are Completely Non-Invasive and Install in Seconds

HANI sensors, as their name implies (High-Accuracy, Non-Invasive), are completely non-invasive. They simply clamp to the outside of a desired pipe, and they are capable of measuring the temperature inside that pipe, accurately, in seconds. Because nothing needs to go in the pipe – no sensor probes, no thermowells, nothing – there’s no need to cut into, weld onto, or drill into a pipe to install a HANI sensor. Which means all the costly downtime related to invasive installation measures are completely eliminated.

And HANI sensors are highly accurate. In fact, Omega’s sensor technology and proprietary algorithm enable HANI sensors to offer accuracy (±0.5°C = ±0.9°F) and response times (t63 = 5 sec) comparable to the thermocouples and RTDs dairy producers begrudgingly use.

2. HANI Sensors Provide Needed Versatility

Often, when areas of dairy processing systems are hard to get to (or if the expensive process of installing in-pipe sensors is not a realistic option), temperatures for the CIP process are estimated instead of measured. Or, to ensure that temperature specifications are met, CIP systems are run to their maximum.

HANI sensors, however, can be quickly attached for accurate, on-the-spot measurement – completely eliminating any potential installation costs. These sensors, which are compact and extremely versatile in design, clamp-on to a desired pipe and the quick-latch mechanism automatically sets the tension for the specified pipe diameter.

And, if temperature measurements are needed in different locations throughout the CIP system at different times, the HANI sensor is simply un-clamped and moved to the needed location. The same HANI sensor, for example, can be used to measure both the temperature of the caustic soda solution during the caustic wash stage of the CIP process as well as the nitric acid solution during an acid wash.

3. HANI Sensors Eliminate Sensor Drift and Contamination Risks

Over the course of everyday dairy production, residual process media - from products such as yogurt, milk, and butter - as well as potential inclusions within that process media, can build up around sensor probes, thermowells, or even in the recesses of “Tee” fittings. This buildup can lead to sensor drift, resulting in loss of accuracy. And even with the most robust cleaning system in place, these buildups can lead to bacteria growth and, ultimately, potential contamination.

HANI sensors, being completely non-invasive, require zero direct contact with media. They simply clamp on to the outside of a pipe and can begin measuring the temperature of the media inside the pipe, accurately, in seconds. There are no sensor probes necessary – and no contact means no contamination risk, no sensor drift risk, no clogged pipes, no reduced flow, and, most importantly, no wasted product.

4. HANI Sensors Let The ‘Pig’ Fly!

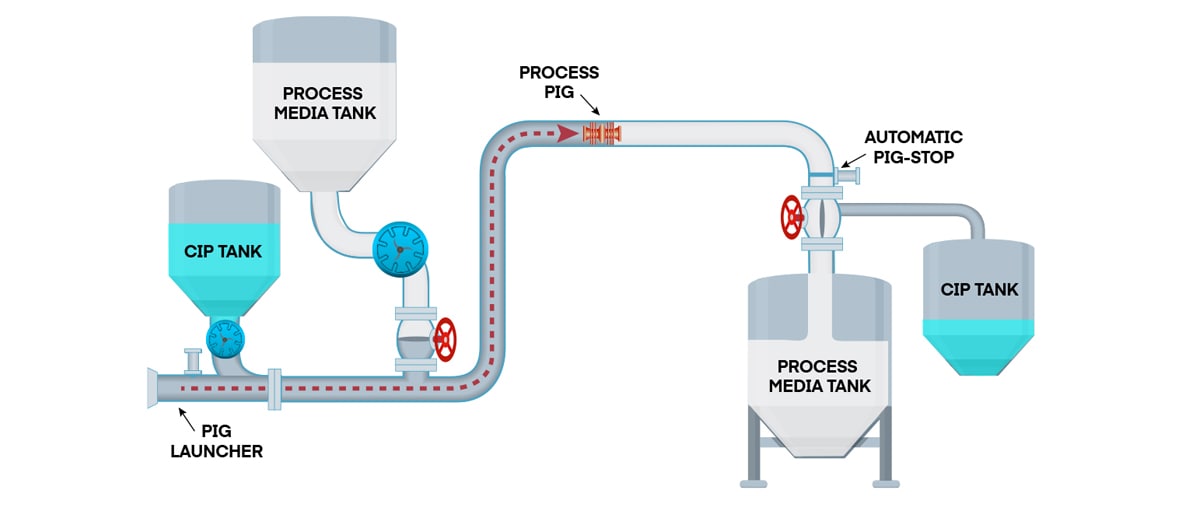

In order to increase product yields and reduce costs in manufacturing industries like dairy production, product recovery – or “pigging” – systems are used to recover any residual product left in the piping system. A pigging system consists of the ‘pig’, which is a solid projectile or plug, that has a diameter slightly larger than the pipeline or tubing that is transporting the liquid. The ‘pig’ is introduced into the pipeline and is pushed through the pipe – forcing all residual product along with it.

However, while a pigging system is effective in reducing the amount of time, water, chemicals, labor, and energy needed to run a CIP system, the invasive in-pipe temperature sensors that are necessary to monitor in-pipe temperature become problematic. These sensor probes – as well as the protective thermowells installed to house them – impede the ‘pig’, making the process impossible without removing them first. And costly added downtime is the inevitable result.

Since HANI sensors are completely non-invasive, the product recovery system can run without the need to remove anything from the system. Simply put, there is nothing to ‘block the pig’.