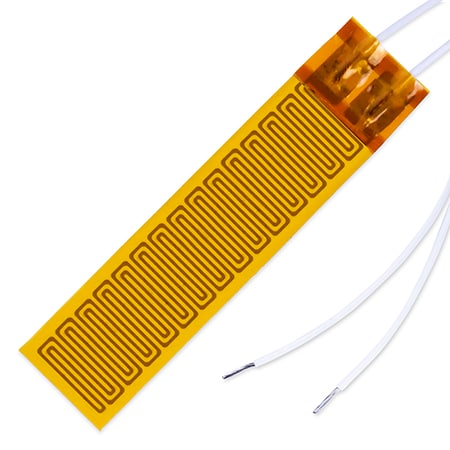

A flexible heater is a versatile heating device designed to be lightweight, adaptable, and capable of conforming to the shape of the object or surface it is intended to heat. Unlike traditional rigid heating elements, flexible heaters can bend, stretch, or even wrap around surfaces – making them ideal for use in confined spaces or on irregularly shaped objects. There are many varieties of flexible heaters, and they are typically made from materials such as silicone rubber, polyimide (Kapton), or thin metal foil, which offer both flexibility and high heat resistance, ensuring reliable and efficient heating in various environments.

Advantages of Flexible Heaters

The primary advantage of flexible heaters lies in their remarkable customizability, which makes them an ideal solution for a wide variety of applications across different industries. These heaters can be manufactured in an extensive range of sizes, shapes, and configurations, allowing them to be tailored precisely to meet the specific heating needs of any given system. Whether it's a compact heating pad for medical use, a complex component in industrial machinery, or an integral part of automotive equipment such as heated seats or mirrors, flexible heaters can be designed to fit seamlessly into these diverse environments. Their ability to conform to irregular surfaces or fit into tight spaces makes them especially valuable in applications where traditional, rigid heating elements would be impractical or inefficient.

Flexible heaters are engineered to provide targeted and efficient heat distribution, ensuring that heat is applied where it is needed most without wastage. This precision in heating helps optimize energy consumption and maintain consistent temperatures in sensitive applications, from manufacturing processes to comfort features in vehicles. Furthermore, flexible heaters can be easily integrated with advanced temperature controllers to regulate heat output and ensure that the desired temperature is achieved and maintained throughout their operation. This integration allows for real-time monitoring and adjustments, ensuring precise, consistent heating performance even in demanding conditions, making flexible heaters ideal for industries that require high levels of control and reliability.

Discover Omega's Selection of Flexible Heaters

Flexible Heaters in Action - Applications

Flexible heaters are widely used across various industries due to their versatility, space-saving design, and efficient heating capabilities. In industrial settings, they are particularly valuable for heating tanks, pipes, and valves, especially in environments where temperatures can drop below freezing. Flexible heaters are wrapped around these components to prevent freezing and ensure the consistent flow of materials like chemicals, oils, or water. They are also used in molding applications, where precise and uniform heating is required for molds and tooling, such as in plastic injection molding, aerospace manufacturing, and automotive production. By providing controlled heat, flexible heaters improve product quality, reduce cycle times, and enhance manufacturing efficiency.

In the medical field, flexible heaters play a critical role in ensuring the safe warming of medical equipment and patients. They are often used in patient warming blankets, incubators, and other medical devices to maintain a consistent and comfortable temperature. The flexibility of these heaters allows them to be integrated into a variety of medical equipment, ensuring both safety and comfort without compromising the equipment's design or mobility. Additionally, they are used in instruments that require precise temperature control for accurate readings or processes, making them essential in hospitals and clinics.

The automotive sector also benefits from flexible heaters, particularly in preventing freezing of components and providing enhanced comfort in vehicles. For example, they are commonly used in heated seats, steering wheels, and mirrors to improve driver and passenger comfort in cold weather. Flexible heaters are also applied in critical automotive parts, such as battery compartments, to regulate temperature and prevent performance issues in extreme temperatures. Their energy efficiency, lightweight nature, and durability make flexible heaters a practical solution in environments where traditional rigid heating methods would be cumbersome, inefficient, or unsuitable, further enhancing their versatility and reliability in a wide range of applications.

Omega Ingenuity

Omega Engineering provides an extensive selection of flexible heaters, with temperature capabilities reaching up to 450 °F. Available in different sizes and materials, including silicone rubber, fiberglass, and polyimide, these heaters are designed to withstand harsh conditions. Their resistance to moisture, chemicals, and environmental factors makes them an ideal choice for applications such as freeze protection, heating enclosures, warming drums, and much more. Whether you need reliable heat for industrial processes or precise temperature control in sensitive environments, Omega's flexible heaters offer a practical, durable, and efficient solution.