Thermal, vibrating, and optical level switches are specialty devices developed to solve specific level detection problems. Typically, they are used in applications that either cannot be handled by the more common float and probe-type devices, or when ultrasonic, nuclear, radar or microwave designs would be too sophisticated, expensive, or otherwise unsuited for the task.

All three types can be used to detect liquid levels or interfaces between liquids. The optical level switch is also suited for detecting high foam levels, if it is spray washed after each event. In some specialized applications, all three of these switches have been tuned to identify specific materials or to determine when a material reaches a particular viscosity, density, opacity, or thermal conductivity condition.

All three level switch designs are simple, straightforward, and reliable. Although some can detect other process properties besides level, their main purpose is to measure the presence or absence of material at a particular level in a tank.

These switches are good candidates for use in multiple purpose processing equipment where they must be compatible with a variety of process materials and process conditions. They do not require recalibration between batches and can be cleaned in place.

Vibrating probe-type sensors are often used to detect solid materials such as powders, bulk solids, grain, flour, plastic granules, cement, and fly ash. They provide excellent performance as high or low level switches and can be mounted from the tops or sides of tanks. The low thermal conductivity of solids and the dusty atmospheres that are likely to exist in the vapor space of solids bins tend to exclude the use of optical and thermal switches from most solids level measurement applications.

When solid materials rat-hole or bridge, few level sensors (except load

cells or radiation devices) work well. The performance of vibrating probe and tuning-fork sensors is also questionable in such services, but their vibrating nature can help to collapse the bridges or to break up the rat-holes.

Vibrating and tuning fork probes can tolerate a fair amount of material build-up, or, if coated with PFA, can be self-cleaning in some less difficult services. Optical level switches are available with automatic washers to remove the build-up of coating after each high level episode. Thermal switches can continue to work when lightly coated, but build-up does usually add a thermally insulating layer, ultimately slowing response time.

Of the three level-switch designs discussed in this chapter, only the laser-based optical level switch is appropriate for use in molten metal level detection. Of the other level sensor technologies, refractory floats, refractory bubbler tubes, and proximity-type capacitance detectors also are used in molten metal service.

Thermal Switches

Thermal level switches sense either the difference between the temperatures of the vapor space and the liquid or, more commonly, the increase in thermal conductivity as a probe becomes submerged in the process liquid.

One of the simplest thermal level switch designs consists of a temperature sensor heated with a constant amount of heat input. As long as the probe is in the vapor space, the probe remains at a high temperature, because low-conductivity vapors do not carry much heat away from the probe. When the probe is submerged, the liquid absorbs more heat and the probe temperature drops. The switch is actuated when this

change in temperature occurs.

Another type of thermal sensor uses two resistance temperature detectors (RTDs), both mounted at the same elevation. One probe is heated and the other provides an unheated reference. The outputs of both sensors are fed into a Wheatstone bridge (Figure 10-1). While the sensor is in the vapor phase, the heated probe will be warmer than the reference probe, and the bridge circuit will be unbalanced. When both probes are submerged in the process liquid, their temperatures will approach that of the liquid. Their outputs will be nearly equal and the bridge will be in balance. This level switch is actuated when a change in bridge balance occurs.

Since all process materials have a characteristic heat transfer coefficient, thermal level switches can be calibrated to detect the presence or absence of any fluid. Therefore, these switches can be used in difficult services, such as interfaces, slurry, and sludge applications. They can also detect thermally conductive foams if spray-cleaned after each operation.

Thermal level and interface switches have no mechanical moving parts and are rated for pressures up to 3,000 psig and process temperatures from -75 to 175°C (-100 to 350°F). When detecting water level, response time is typically 0.5 second and accuracy is within 2 mm. In general, thermal level switches work best with non-coating liquids and with slurries having 0.4-1.2 specific gravity and 1-300 cP viscosity.

A third type of thermal switch also uses two sensors inside the same vertical probe. One is mounted above the other and both are connected to a voltage source. When both are in the vapor or both in the liquid phase, the current flow through the two sensors is the same. If, on the other hand, the lower one is in liquid and the upper in vapor, more current will flow through the lower sensor. A current comparator can detect this difference and signal that the sensor has reached the vapor/liquid interface.

One interesting feature of this design is that the sensor capsule can be suspended by a cable into a tank or well, and the sensor output can be used to drive the cable take-up motor. In this fashion, the level switch can be used as a continuous detector of the location of the vapor/liquid interface.

Thermometers also can be used to detect level in higher temperature processes, such as measuring the level of molten steel in casting molds. The thermometers do not actually touch the molten metal; instead, they identify the place where the temperature on the outside of the mold suddenly increases. This is the level inside the mold. Using multiple sensors spaced vertically, the system can determine the level of molten metal in the mold to within a fraction of an inch.

Vibrating Switches

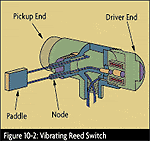

Vibrating level switches detect the dampening that occurs when a vibrating probe is submerged in a process medium. The three types of vibrating sensors--reed, probe, and tuning fork--are distinguished by their configurations and operating frequencies (120, 200-400, and 85 Hz, respectively). Their methods of operation and applications are similar. The reed switch consists of a paddle, a driver and a pickup (Figure 10-2). The driver coil induces a 120-Hz vibration in the paddle that is damped out when the paddle gets covered by a process material. The switch can detect both rising and falling levels, and only its actuation depth (the material depth over the paddle) increases as the density of the process fluid drops. The variation in actuation depth is usually less than an inch. A reed switch can detect liquid/liquid, liquid/vapor, and solid/vapor interfaces, and can also signal density or viscosity variations.

When used on wet powders, the vibrating paddle has a tendency to create a cavity in the granular solids. If this occurs, false readings will result, because the sensor will confuse the cavity with vapor space.

It is best to use a reed switch on non-coating applications or to provide automatic spray washing after each immersion in a sludge or slurry. Probe-type vibrating sensors are less sensitive to material build-up or coating. The vibrating probe is a round stainless steel element (resembling a thermowell) that extends into the material. If PFA coated and inserted at an angle, these devices tend to be self-cleaning. Both the drive and the sensor are piezoelectric elements: one causes the vibration and the other measures it. When the probe is buried under the process

material, its vibration is dampened and this decrease triggers the switch.

Vibrating probe sensors can be used to monitor powders, bulk solids, and granular materials such as grain, flour, plastic pellets, cement, and fly ash. Their vibrating nature tends to minimize the bridging that occurs in solid materials. Tuning fork sensors are vibrated at about 85 Hz by one piezoelectric crystal, while another piezoelectric crystal detects the vibration. As the process fluid rises to cover the tuning forks, the vibration frequency changes.

Like vibrating probes, tuning-fork designs can be self-cleaning if PFA coated and installed at an angle. They can also be calibrated to detect a wide range of materials, including lubricating oils, hydraulic fluids, water, corrosive materials, sand, thick and turbulent fluids, powders, light granules, and pastes.

Tuning-fork sensors can be constructed with components made of PVDF, polypropylene, stainless steel, carbon steel, and aluminum. They are available with PFA coatings or in hygienic versions for sanitary applications.

Vibrating sensors can be used to ascertain liquid, solid, and slurry levels. Reed switches can operate at pressures up to 3,000 psig, while tuning forks and vibrating probes are limited to 150 psig. Operating temperatures range from -100 to 150°C (-150 to 300°F) and response time is about 1 second.

Optical Switches

Using visible, infrared, or laser light, optical sensors rely upon the light transmitting, reflecting, or refracting properties of the process material when measuring its level. The optical level switch can be of a contacting or

non-contacting design.

In a non-contacting, reflecting optical sensor, a beam of light is aimed down at the surface of the process material. When the level of this surface rises to the setpoint of the switch, the reflected light beam is detected by a photocell. Both the LED light source and photodetector are housed behind the same lens.

By adjusting the photocell or the detection electronics, the sensor can be calibrated to detect levels at distances 0.25 to 12 in below the sensor. These reflective switches can measure the levels of clear as well as translucent, reflective, and opaque liquids. Some solids also can be detected. By using multiple photocells, a sensor can detect several levels.

Laser light also can be used when making difficult level measurements, such as of molten metals, molten glass, glass plate, or any other kind of solid or liquid material that has a reflecting surface. If the receiver module is motor driven, it can track the reflected laser beam as the level rises and falls, thereby acting as a continuous level transmitter.

A refracting sensor relies on the principle that infrared or visible light changes direction (refracts) when it passes through the interface between two media. When the sensor is in the vapor phase, most of the light from the LED is reflected back within a prism (Figure 10-3). When the prism is submerged, most of the light refracts into the liquid, and the amount of reflected light that reaches the receiver drops substantially. Therefore, a drop in the reflected light signal indicates contact with the process liquid.

A refracting sensor cannot be used with slurries or coating liquids, unless it is spray-washed after each submersion. Even a few drops of liquid on the prism will refract light and cause erroneous readings. Refracting sensors are designed to be submerged in liquids; therefore, any number of them can be installed on a vertical pipe to detect a number of level points.

Transmission optical sensors send a beam of light across the tank. A sludge level sensor of this design uses an LED and a photocell at the end of a probe, located at the same elevation and separated by a few inches. To find the sludge level, a mechanism (or an operator, manually) lowers the probe into the tank until the sensors encounter the sludge layer.

Other transmission sensors rely on the refraction principle utilizing an unclad, U-shaped fiber optic cable. A light source transmits a pulsed light beam through the fiber cable, and the sensor measures the amount of light that returns. If liquid covers the cable, it will cause light to refract away from the cable. The use of fiber-optics makes the system impervious to electrical interference, and some designs are also intrinsically safe.

Optical sensors can operate at pressures up to 500 psig and temperatures up to 125°C (260°F). Response time is virtually immediate, and detection accuracy of most designs is within 1 mm. Optical level switches are also designed for specific or unique applications. For example, PFA optical level switches are available for sensing the level of ultra-pure fluids. Other unique designs include a level switch that combines an optical with a conductivity-type level sensor to detect the presence of both water (conductive) and hydrocarbons (nonconductive).