Turbine flow meters are a type of velocity flow meter that have found widespread use in a variety of industrial applications – including aerospace, cryogenic, and custody transfer – for high accuracy measurements. Invented by Reinhard Woltman in the 18th century, the turbine flow meter is reliable for use with both liquids and gases. It consists of a multi-bladed rotor mounted at right angles to the fluid flow and suspended in the fluid stream on a free-running bearing. The diameter of the rotor is very slightly less than the inside diameter of the metering chamber, and its speed of rotation is proportional to the volumetric flow rate. Turbine rotation can be detected by solid state devices (reluctance, inductance, capacitive and Hall-effect pick-ups) or by mechanical sensors (gear or magnetic drives).

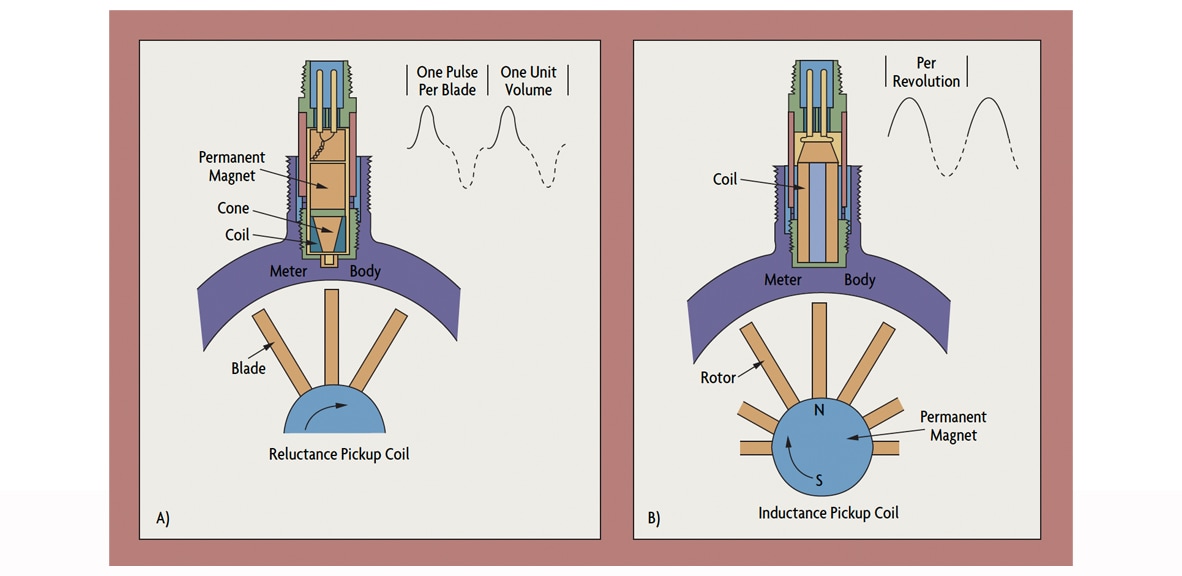

In the reluctance pick-up, the coil is a permanent magnet and the turbine blades are made of a material attracted to magnets. As each blade passes the coil, a voltage is generated in the coil (Figure 1-A). Each pulse represents a discrete volume of liquid. The number of pulses per unit volume is called the meter's K-factor.

Figure 1: Generation of Turbine Flow Signal

Figure 1: Generation of Turbine Flow Signal

In the inductance pick-up, the permanent magnet is embedded in the rotor, or the blades of the rotor are made of permanently magnetized material (Figure 1-B). As each blade passes the coil, it generates a voltage pulse. In some designs, only one blade is magnetic, and the pulse represents a complete revolution of the rotor.

The outputs of reluctance and inductive pick-up coils are continuous sine waves with the pulse train's frequency proportional to the flow rate. At low flow rates, the output (the height of the voltage pulse) may be on the order of 20 mV peak-to-peak. It is not advisable to transport such a weak signal over long distances. Therefore, the distance between the pickup and associated display electronics or preamplifier must be short.

Capacitive sensors produce a sine wave by generating an RF signal that is amplitude-modulated by the movement of the rotor blades. Instead of pick-up coils, Hall-effect transistors also can be used. These transistors change their state when they are in the presence of a very low strength (on the order of 25 gauss) magnetic field.

In these turbine flow meters, very small magnets are embedded in the tips of the rotor blades. Rotors are typically made of a non-magnetic material, like polypropylene, Ryton, or PVDF (Kynar). The signal output from a Hall-effect sensor is a square wave pulse train, at a frequency proportional to the volumetric flowrate.

Because Hall-effect sensors have no magnetic drag, they can operate at lower flow velocities (0.2 ft/sec) than magnetic pick-up designs (0.5-1.0 ft/sec). In addition, the Hall-effect sensor provides a signal of high amplitude (typically a 10.8-V square wave), permitting distances up to 3,000 ft. between the sensor and the electronics without amplification.

In the water distribution industry, mechanical-drive Woltman-type turbine flow meters continue to be the standard. These turbine meters use a gear train to convert the rotation of the rotor into the rotation of a vertical shaft. The shaft passes between the metering tube and the register section through a mechanical stuffing box, turning a geared mechanical register assembly to indicate flow rate and actuate a mechanical totalizer counter.

More recently, the water distribution industry has adopted a magnetic drive as an improvement over high maintenance mechanical-drive turbine meters. This type of meter has a sealing disc between the measuring chamber and the register. On the measuring chamber side, the vertical shaft turns a magnet instead of a gear. On the register side, an opposing magnet is mounted to turn the gear. This permits a completely sealed register to be used with a mechanical drive mechanism.

In the United States, the AWWA sets the standards for turbine flow meters used in water distribution systems. Standard C701 provides for two classes (Class I and Class II) of turbine flow meters. Class I turbine meters must register between 98-102% of actual rate at maximum flow when tested. Class II turbine meters must register between 98.5-101.5% of actual rate. Both Class I and Class II meters must have mechanical registers.

Solid state pickup designs are less susceptible to mechanical wear than AWWA Class I and Class II meters.

Design and Construction Variations

Most industrial turbine flow meters are manufactured from austenitic stainless steel (301, 303, 304SS), whereas turbine meters intended for municipal water service are bronze or cast iron. The rotor and bearing materials are selected to match the process fluid and the service. Rotors are often made from stainless steel, and bearings of graphite, tungsten carbide, ceramics, or in special cases of synthetic ruby or sapphire combined with tungsten carbide. In all cases, bearings and shafts are designed to provide minimum friction and maximum resistance to wear. Some corrosion-resistant designs are made from plastic materials such as PVC.

Small turbine meters often are called barstock turbines because in sizes of 3/4 in to 3" they are machined from stainless steel hexagonal barstock. The turbine is suspended by a bearing between two hanger assemblies that also serve to condition the flow. This design is suited for high pressure (up to 5,000 psig).

Similar to a pitot tube differential pressure flow meter, the insertion turbine meter is a point-velocity device. It is designed to be inserted into either a liquid or a gas line to a depth at which the small-diameter rotor will read the average velocity in the line. Because they are very sensitive to the velocity profile of the flowing stream, they must be profiled at several points across the flow path.

Insertion turbine meters can be designed for gas applications (small, lightweight rotor) or for liquid (larger rotor, water-lubricated bearings). They are often used in large diameter pipelines where it would be cost-prohibitive to install a full-size meter. They can be hot-tapped into existing pipelines (6" or larger) through a valving system without shutting down the process. Typical accuracy of an insertion turbine meter is 1% FS, and the minimum flow velocity is about 0.2 ft/sec.

Turbine Meter Accuracy

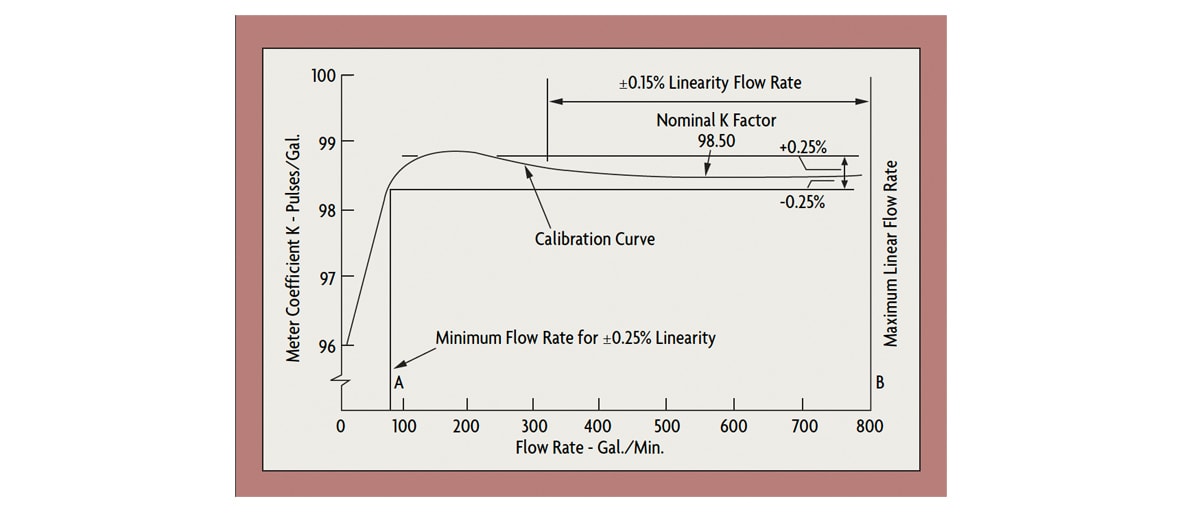

Figure 2 shows a typical turbine-meter calibration curve describing the relationship between flow and K-factor (pulses/gallon). The accuracy of turbine meters is typically given in percentage of actual rate (% AR). This particular meter has a linearity tolerance band of ±0.25% over a 10:1 flow range and a ±0.15% linearity in a 6:1 range. The repeatability is from ±0.2% to ±0.02% over the linear range.

Figure 2: Typical Turbine Flow Meter Calibration Curve

Figure 2: Typical Turbine Flow Meter Calibration Curve

Because there are minor inconsistencies in the manufacturing process, all turbine flow meters are calibrated prior to shipment. The resulting K-factor in pulses per volume unit will vary within the stated linearity specification. It is possible, however, to register several K-factors for different portions of the flow range and to electronically switch from one to the other as the measured flow changes. Naturally, the K-factor is applicable only to the fluid for which the meter was calibrated.

Barstock turbine meters typically are linear to ±0.25% AR over a 10:1 flow range. The linearity of larger meters is ±0.5% AR over a 10:1 flow range. Turbine meters have a typical nonlinearity (the turbine meter hump, shown in Figure 2) in the lower 25-30% of their range. Keeping the minimum flow reading above this region will permit linearity to within 0.15% on small and 0.25% on larger turbine meters. If the range of 10:1 is insufficient, some turbine flow- meters can provide up to 100:1 turn-downs if accuracy is de-rated to 1% of full scale (FS).

Sizing and Selection

Turbine meters should be sized so that the expected average flow is between 60% and 75% of the maximum capacity of the meter. If the pipe is oversized (with flow velocity under 1 ft/sec), one should select a Hall-effect pick-up and use a meter smaller than the line size. Flow velocities under 1 ft/sec can be insufficient, while velocities in excess of 10 ft/sec can result in excessive wear. Most turbine meters are designed for maximum velocities of 30 ft/sec.

Turbine flow meters should be sized for between 3 and 5 psid pressure drop at maximum flow. Because pressure drop increases with the square of flow rate, reducing the meter to the next smaller size will raise the pressure drop considerably.

Viscosity affects the accuracy and linearity of turbine meters. It is therefore important to calibrate the meter for the specific fluid it is intended to measure. Repeatability is generally not greatly affected by changes in viscosity, and turbine meters often are used to control the flow of viscous fluids. Generally, turbine meters perform well if the Reynolds Number is greater than 4,000 and less than or equal to 20,000.

Because it affects viscosity, temperature variation can also adversely affect accuracy and must be compensated for or controlled. The turbine meter's operating temperature ranges from -200 to 450°C (-328 to 840°F).

Density changes do not greatly affect turbine meters. On low density fluids (SG < 0.7), the minimum flow rate is increased due to the reduced torque, but the meter's accuracy usually is not affected.

Installation and Accessories

Turbine meters are sensitive to upstream piping geometry that can cause vortices and swirling flow. Specifications call for 10-15 diameters of straight run upstream and five diameters of straight run downstream of the meter. However, the presence of any of the following obstructions upstream would necessitate that there be more than 15 diameters of upstream straight-pipe runs.

- 20 diameters for 90° elbow, tee, filter, strainer, or thermowell;

- 25 diameters for a partially open valve; and

- 50 or more diameters if there are two elbows in different planes or if the flow is spiraling or corkscrewing.

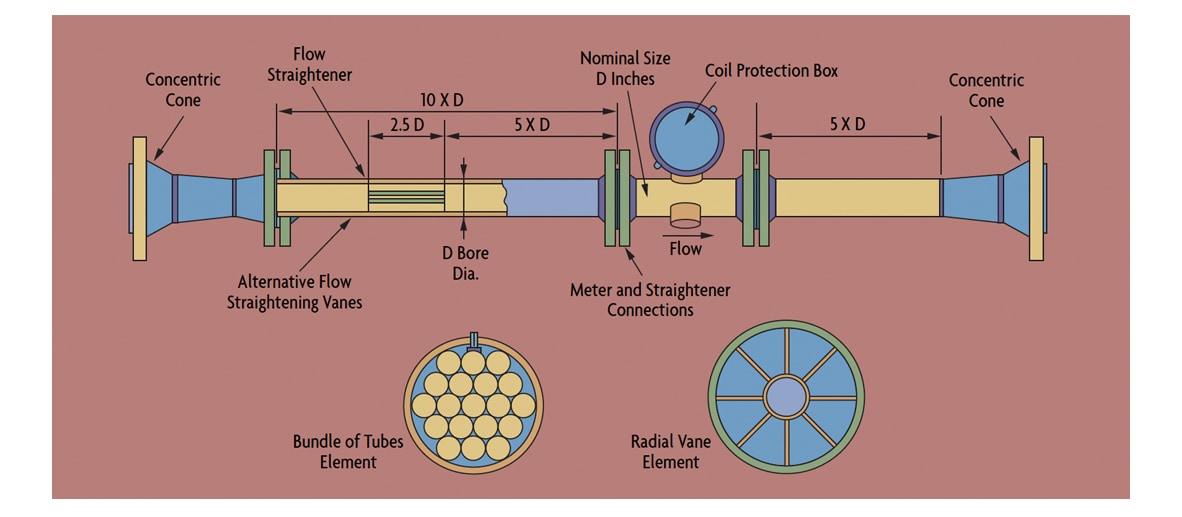

In order to reduce this straight-run requirement, straightening vanes are installed. Tube bundles or radial vane elements are used as external flow straighteners located at least 5 diameters upstream of the meter (Figure 3).

Figure 3: Flow Straighteners Reduce Straight Pipe Runs

Figure 3: Flow Straighteners Reduce Straight Pipe Runs

Under certain conditions, the pressure drop across the turbine can cause flashing or cavitation. The first causes the meter to read high, the second results in rotor damage. In order to protect against this, the downstream pressure must be held at a value equaling 1.25 times the vapor pressure plus twice the pressure drop. Small amounts of air entrainment (100 mg/l or less) will make the meter read only a bit high, while large quantities can destroy the rotor.

Turbine meters also can be damaged by solids entrained in the fluid. If the amount of suspended solids exceeds 100 mg/l of +75 micron size, a flushing y-strainer or a motorized cartridge filter must be installed at least 20 diameters of straight run upstream of the flow meter.

New Developments

Dual-rotor liquid turbines increase the operating range in small line size (under 2 in) applications. The two rotors turn in opposite directions. The front one acts as a conditioner, directing the flow to the back rotor. The rotors lock hydraulically and continue to turn as the flow decreases even to very low rates.

The linearity of a turbine meter is affected by the velocity profile (often dictated by the installation), viscosity, and temperature. It is now possible to include complex linearization functions in the preamplifier of a turbine flow meter to reduce these nonlinearities. In addition, advances in fieldbus technology make it possible to recalibrate turbine flow meters continuously, thereby correcting for changes in temperature and viscosity.

Flow computers are capable of linearization, automatic temperature compensation, batching, calculation of BTU content, datalogging, and storage of multiple K-factors. The batching controller is set with the desired target volume and, when its totalizer has counted down to zero, it terminates the batch. Such packages are equipped with dribble flow, pre-warn, or trickle-cut-off circuits. Whether functioning through a relay contact or a ramp function, these features serve to minimize splashing or overfill and to accurately terminate the batch.

Gas Turbine and Shunt Meters

Gas meters compensate for the lower driving torque produced by the relatively low density of gases. This compensation is obtained by very large rotor hubs, very light rotor assemblies, and larger numbers of rotor blades. Gas flow turbine meters are available from 2" to 12" and with flow ratings up to 150,000 ft3/hr. When operating at elevated gas pressures (1,400 psig), a rangeability of 100:1 can be obtained in larger size meters. Under lower pressure conditions, typical rangeability is 20:1 with ±1% linearity. The minimum upstream straight pipe-run requirement is 20 pipe diameters.

Shunt flow meters are used in gas and steam service. They consist of an orifice in the main line and a rotor assembly in the bypass. These meters are available is sizes 2 in. and larger and are accurate to ±2% over a range of 10:1.

Other Rotary Flow Meters

Other types of rotary element flow meters include propeller (impeller), shunt, and paddlewheel designs.

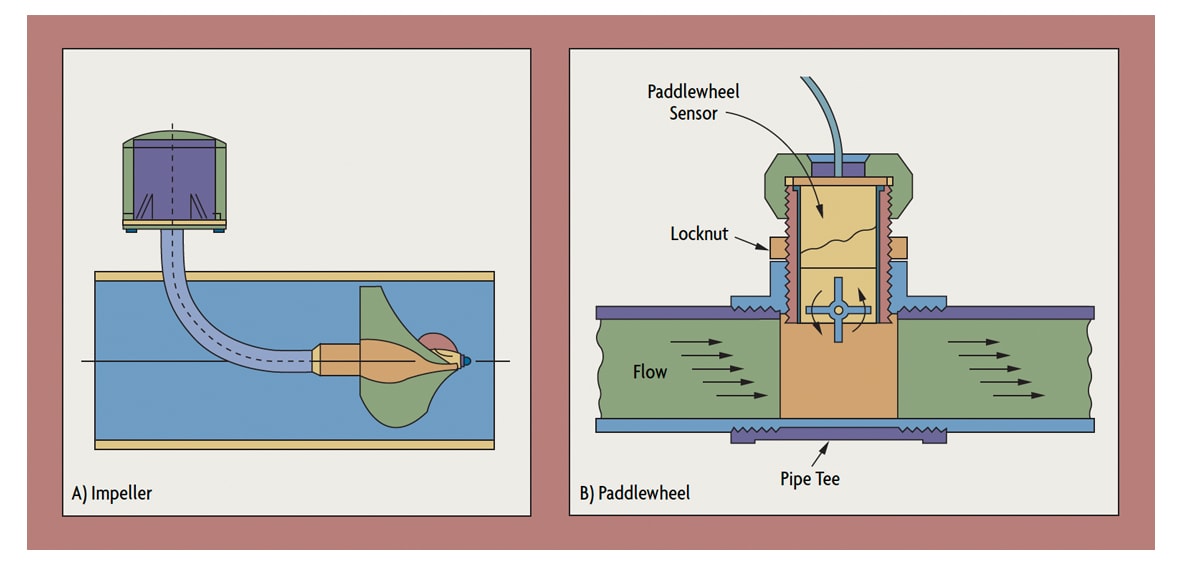

Propeller meters are commonly used in large diameter (over 4") irrigation and water distribution systems. Their primary trade-off is low cost and low accuracy (Figure 4-A). AWWA Standard C-704 sets the accuracy criterion for propeller meters at 2% of reading. Propeller meters have a rangeability of about 4:1 and exhibit very poor performance if the velocity drops below 1.5 ft/sec. Most propeller meters are equipped with mechanical registers. Mechanical wear, straightening, and conditioning requirements are the same as for turbine meters.

Figure 4: Rotary Flow Meter Designs

Figure 4: Rotary Flow Meter Designs

Paddlewheel flow meters use a rotor whose axis of rotation is parallel to the direction of flow (Figure 4-B). Most paddlewheel meters have flat-bladed rotors and are inherently bi-directional. Several manufacturers, however, use crooked rotors that only rotate in the forward direction. For smaller pipes (1/2" to 3"), these meters are available only with a fixed insertion depth, while for larger pipe sizes (4" to 48") adjustable insertion depths are available. The use of capacitively coupled pick-ups or Hall-effect sensors extends the range of paddlewheel meters into the low-flow velocity region of 0.3 ft/sec.

Low-flow meters (usually smaller than 1 in.) have a small jet orifice that projects the fluid onto a Pelton wheel. Varying the diameter and the shape of the jet orifice matches the required flow range and provides a flow meter that is accurate to 1% FS and has a rangeability of 100:1. Higher accuracy can be achieved by calibrating the meter and by lowering its range. Because of the small size of the jet orifice, these meters can only be used on clean fluids and they incur a pressure drop of about 20 psid. Materials of construction include polypropylene, PVDF, TFE and PFA, brass, aluminum, and stainless steel.