An Introduction to pH Meters and pH Electrodes

Since accurate measurement of pH values of specific solutions or substances is an essential variable in many situations, pH meters are commonly used instruments in many industrial applications. A pH meter is an electric device that measures hydrogen-ion activity (acidity or alkalinity) in a solution – which is, ultimately, expressed as a pH value – and consists of a voltmeter that is connected to a pH-measuring electrode and a reference electrode.

What is a pH Electrode?

pH electrodes, which are analytical sensors, are used to measure the potential of hydrogen (pH), or the negative logarithm of the hydrogen ion activity, in a solution. The technology behind pH electrodes has not changed much in the past half-century or so, yet pH electrode manufacturing remains an art. pH electrodes are constructed from a special composition glass which can sense the hydrogen ion concentration. The special glass body of an electrode is blown to its configuration by glass blowers and is neither a terribly advanced nor particularly ‘high tech’ process, but a very critical and important step in pH electrode manufacturing, nonetheless.

Combination pH Electrodes

In a combination pH electrode, which is the most widely used variety of electrode, the pH-measuring electrode and the reference are housed in one body. The potential generated at the junction site of the measuring portion is due to the free hydrogen ions present in a particular solution. The potential of the reference portion is produced by the internal element in contact with the reference fill solution – and this potential is always constant. With a combination pH electrode, the measuring electrode delivers a varying voltage, and the reference electrode delivers a constant voltage to the meter. The voltage signal produced by the pH electrode is a very small, high impedance signal. The input impedance requires that it be interfaced only with equipment with high impedance circuits. The input impedance required is greater than 1013 ohms – which is why pH electrodes do not interface directly with all equipment.

Glass-bodied and Refillable Combination pH Electrodes

Glass-bodied and Refillable Combination pH Electrodes

Combination pH electrodes are available in a variety of styles for both laboratory and industrial applications. All are composed of a glass and are therefore subject to breakage. Electrodes are designed to measure mostly aqueous media. They are not designed to be used in solvents, such as CC14, which do not have any free hydrogen ions.

It is essential, due to the nature of its construction, that a pH electrode is always kept moist. In order to operate properly, the glass body of a pH electrode needs to be hydrated – which is required for the ion exchange process to occur. If an electrode should become dry, it is best to place it in some tap water for a half hour condition the glass.

Combination pH electrodes are like batteries; they run down time and use. As an electrode ages, its glass body changes resistance. This resistance change alters the electrode potential, and, for this reason, electrodes need to be calibrated on a regular basis. Calibration in pH buffer solution corrects for this change. Calibration of any pH equipment should always begin with buffer 7.0 as this is the ‘zero point’. The pH scale has an equivalent mV scale. The mV scale ranges from +420 to -420 mV. At a pH of 7.0 the mV value is 0. Each pH change corresponds to a change of +/- 60mV. As pH values become more acidic the mV values become greater. For example, a pH of 4.0 corresponds to a value of 180 mV. As pH values become more basic the mV values become more negative; pH = 9 corresponds to -120 mV. Dual calibration using buffers 4.0 or 10.0 provides greater system accuracy.

How Does a Combination pH Electrode Monitor pH?

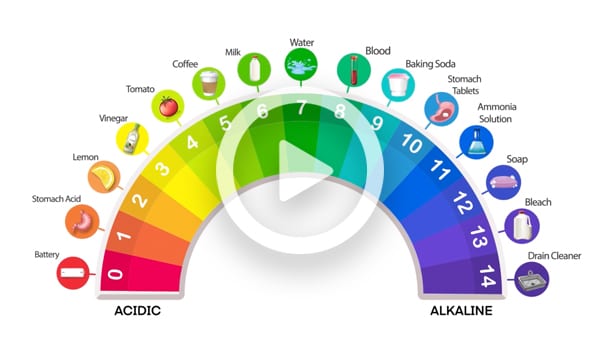

Combination pH electrodes are designed to allow hydrogen ions in the solution to pass through a selective barrier, generating a measurable voltage differential between the pH-measuring electrode and the reference electrode that is proportional to the solution’s pH level. For example, at a pH level of seven, which is neutral, the electrodes will produce zero volts between them. At a lower pH level, acidic, a voltage will be developed of one polarity. At a high pH level, caustic/alkaline, a voltage will be developed of the opposite polarity.

pH Meters

For monitoring pH levels in an industrial application, the combination pH electrode is connected to a pH meter, which is, essentially, a high impedance amplifier that accurately measures the electrode voltages and displays the results directly in pH units on a digital display screen.

Portable pH/mV Temperature Meter

Portable pH/mV Temperature Meter

Combination pH Electrode Maintenance

The junction site of a pH electrode can become clogged by particulates in the solution and can also facilitate poisoning by metal ions present in the solution. If a clogged junction is suspected, it is best to soak the electrode in some warm tap water to dissolve the material and clear the junction. pH electrodes should always be stored in a moistened condition. When not in use it is best to store the electrode in an acidic solution such as a 4.0 buffer. Never store an electrode in distilled or deionized water as this will cause migration of the fill solution from the electrode. pH electrodes have a finite lifespan due to their inherent properties. How long a pH electrode will last will depend on how it is cared for and the solutions it is used to measure. Typically, a gel-filled combination pH electrode will last six months to one year depending on the care and application. Even if an electrode is not used it still ages. On the shelf, the electrode should last approximately a year if kept in a moistened condition. Electrode demise can usually be characterized by a sluggish response, erratic readings or a reading which will not change. When this occurs, an electrode can no longer be calibrated. pH electrodes are fragile and have a limited lifespan. How long an electrode will last is determined by how well the probe is maintained and by the application – the harsher the system, the shorter the lifespan. For this reason, it is always a good idea to have a backup electrode on hand to avoid any system downtime. Calibration is also an important part of electrode maintenance. This assures not only that the electrode is behaving properly, but that the system is operating correctly.