At Omega Engineering, our commitment to fostering engineering innovation extends well beyond the realm of industrial manufacturing, and we recognize the pivotal role STEM education plays in shaping the future of engineering. In our ongoing efforts to empower the next generation of engineering innovators, Omega has made it a cornerstone of its mission to support STEM education – one such way being our various strategic collaborations with student-run engineering programs, like that with Carnegie Mellon Racing.

Carnegie Mellon Racing

Carnegie Mellon Racing is the student engineering team at Carnegie Mellon University, bringing together the university’s brightest minds to design, build, and maintain a fully electric Formula1-style race car to compete with university Formula1 SAE teams around the world. The team provides undergraduates with opportunities for technical and management experience on large scale engineering projects.

With an aim to transform students into effective engineers, leaders, and problem solvers, the Carnegie Mellon Racing team is accessible to all students – regardless of experience level, background, or area of study.

The team has a long history in racing: designing their first combustion race car back in 2002, and, in 2014, becoming one of the first university racing teams to make the switch to an electric powertrain – pioneering the technology. This past year, the team designed and developed an open-wheel all-electric race car that, at the Formula Hybrid + Electric racing competition in New Hampshire, placed 2nd overall and won 1st in the Design, Autocross, and Acceleration events.

This upcoming year, Carnegie Mellon Racing looks to implement multiple changes in order to not only remain as competitive as possible, but to continue its mission of cultivating great engineers.

The two most prominent changes will be related to the chassis and the battery of their race car. While steel-tube chassis have been the team’s go-to, this year the team will look to utilize carbon monocoque chassis – removing mass and, since the team will be able to manufacture their chassis in-house, lowering their carbon footprint.

The team is also changing the architecture of their battery pack, moving away from cylindrical cells to a utilization of pouch cells. This battery pack change will allow for the use of fewer total batteries (150 – down from 1000+), more energy dense packaging, and increased serviceability. With the old battery pack architecture, a single dead cell would require replacing 1/8th of the entire battery. With pouch cells, if a single battery fails, it alone can be replaced, minimizing waste and manufacturing effort.

Omega Ingenuity

In addition to these various changes, the team will have at their disposal high-quality, highly accurate Omega sensing equipment – as Omega has fulfilled a donation of our high-quality biaxial strain gauges.

These transducer quality strain gauges are available in a variety of patterns and cover most transducer design requirements. Rugged construction, high performance, and unparalleled reliability make these gauges suitable for highly accurate static and dynamic transducers. The measuring grid is formed by specially formulated etching constantan foil, which is then completely sealed for long term reliability in a carrier medium composed of polyimide film.

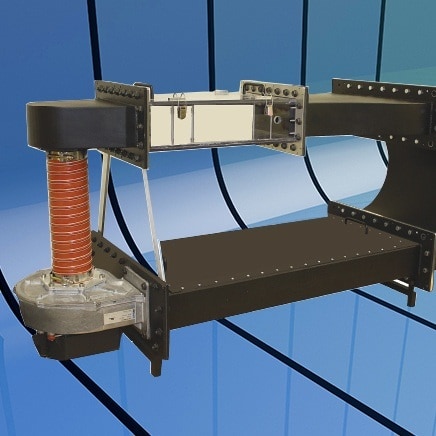

Carnegie Mellon Racing will utilize these strain gauges to validate loads across control arms in their suspension system – which are what attaches the hubs to the rest of the car. The team will use these strain gauges with strain gauge amplifiers – which will reside on one of their custom data acquisition PCBs – and they’ll use the axial strain measurements to validate their design and force calculations, which will help the team improve their suspension system for the future.

To learn more about Omega’s selection of Force and Strain Measurement products, please click here.